Folding Carton vs Corrugated Box

If you’re trying to decide between folding cartons and corrugated boxes, here’s the short answer:

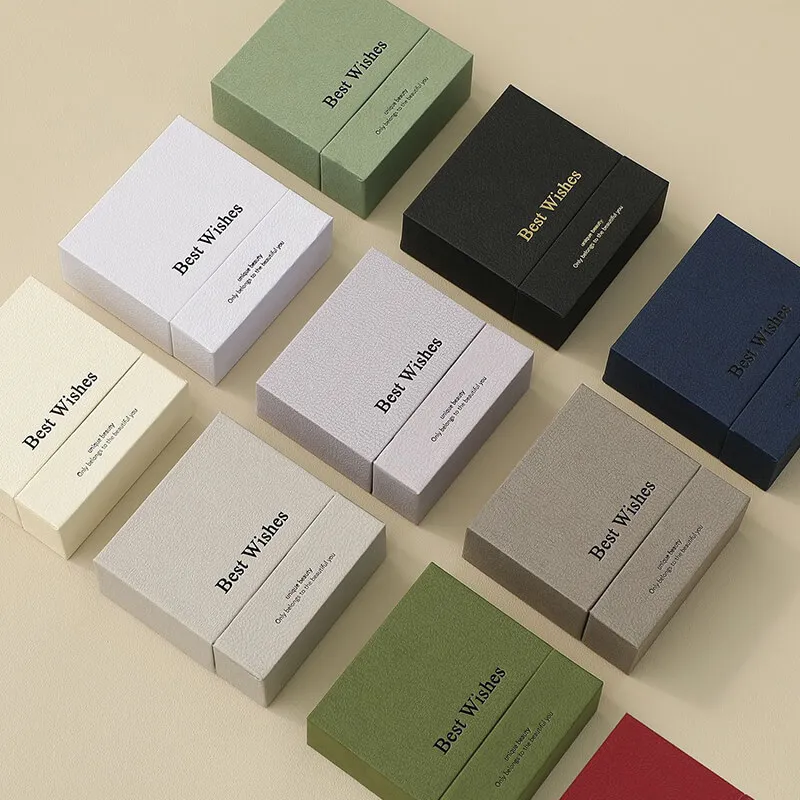

- Use folding cartons when your product is light, needs high-quality graphics, and will be displayed on retail shelves — think cosmetics, pharmaceuticals, or food packaging.

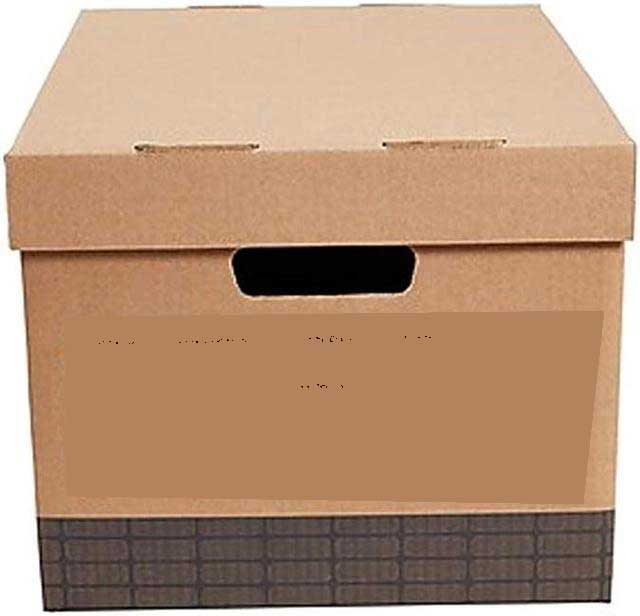

- Choose corrugated boxes when you need a strong, durable structure to protect heavier or fragile items during shipping — like e-commerce orders, bulk products, or home appliances.

In reality, many brands use both: a folding carton for attractive retail appeal, nested inside a corrugated box for safe transport. The smartest choice depends on weight, durability needs, print requirements, and your shipping conditions.

Quick Comparison:

| Feature | Folding Carton | Corrugated Box |

|---|---|---|

| Material Structure | Single-layer paperboard | Multi-layer fluted board |

| Durability | Lightweight | High strength |

| Best Use | Retail display | Shipping & storage |

| Printing | High-end, detailed | Good, but less refined |

| Sustainability | Highly recyclable | Highly recyclable |

| Typical Industries | Cosmetics, pharma | E-commerce, appliances |

What Is a Folding Carton?

A folding carton is a lightweight, single-layer paperboard box that you’ll find almost everywhere on retail shelves. Think of a cereal box, a perfume box, or a small electronics package — that’s your classic folding carton.

Key characteristics:

- Made from solid bleached sulfate (SBS), recycled paperboard, or kraft.

- Usually printed with high-quality graphics and protective finishes to grab attention on shelves.

- Delivered flat to save space, then quickly folded and glued into shape during packing.

Why are folding cartons so popular?

They’re cost-effective for mass production, easy to customize with windows, embossing, foil stamping, or spot UV finishes, and they work beautifully for products that don’t need heavy-duty protection during shipping.

Common industries using folding cartons:

- Cosmetics & beauty: Lipstick boxes, skincare packaging.

- Pharmaceuticals: Medicine boxes, supplement packaging.

- Food & beverage: Tea boxes, snack packs, confectionery packaging.

- Retail goods: Electronics accessories, small consumer items.

Quick takeaway:

When your brand needs stunning visuals and shelf appeal — but not the structural strength of a shipping box — a folding carton is your go-to choice.

What Is a Corrugated Box?

A corrugated box is your reliable workhorse for shipping, storing, and protecting products that need extra strength. Unlike folding cartons, corrugated boxes have a multi-layer structure:

- An outer liner

- A fluted (wavy) middle layer

- An inner liner

This layered design creates air pockets that provide excellent cushioning and stacking strength. That’s why corrugated boxes — also known as shipping boxes or cardboard boxes — are the backbone of e-commerce and bulk shipping.

Key characteristics:

- Available in various flute sizes (like E-flute for retail-ready display boxes, or C-flute for heavier loads).

- Customizable with direct flexo printing, litho lamination, or digital print for colorful branding.

- Can include inserts, partitions, or custom die cuts for extra protection.

Why do so many businesses choose corrugated?

- Superior durability: They handle bumps, drops, and stacking pressure better than single-layer cartons.

- Cost-effective protection: Fewer damaged goods mean lower return rates.

- Versatile formats: From mailer boxes to heavy-duty double-wall cartons for industrial parts.

Common industries using corrugated boxes:

- E-commerce: Subscription boxes, custom mailers.

- Food & beverage: Produce boxes, beverage carriers.

- Electronics & appliances: Shipping fragile, high-value items.

- Retail & wholesale: Master cartons, pallet-ready displays.

Quick takeaway:

When your products are heavy, fragile, or headed through complex supply chains, corrugated boxes are your best bet for strength, protection, and versatility.

Key Differences: Folding Carton vs. Corrugated Box

Now that you know what each is, let’s break down the key differences — so you can decide which works best for your products and supply chain.

| Aspect | Folding Carton | Corrugated Box |

|---|---|---|

| Structure | Single-layer paperboard | Multi-layer with fluted medium for strength |

| Strength & Durability | Good for lightweight to medium items | Excellent for heavy, fragile, or bulky goods |

| Common Uses | Retail shelves, premium display packaging | Shipping boxes, e-commerce, wholesale cartons |

| Print & Branding | High-resolution, vivid graphics | Flexo print, litho lamination, digital options |

| Cost per Unit | Generally lower for small, lightweight items | Slightly higher due to more material and structure |

| Storage & Assembly | Ships flat; easy to assemble | Ships flat; some styles pre-glued or need taping |

| Sustainability | Recyclable, biodegradable | Recyclable, often made with recycled content |

| Customization | Die-cuts, windows, embossing, foils, coatings | Inserts, partitions, special flutes, extra layers |

When to Use Which

- Choose Folding Cartons if your product is lightweight, sold at retail, and needs beautiful shelf appeal.

- Choose Corrugated Boxes if you need shipping strength, stacking ability, and maximum protection during transit.

Pro tip: Many brands actually use both together! For example, a premium folding carton goes inside a sturdy corrugated box for shipping — combining the best of both worlds.

Cost & Production Considerations

When you’re comparing folding cartons and corrugated boxes, cost isn’t just about the price per box — it’s about the whole production puzzle.

| Factor | Folding Carton | Corrugated Box |

|---|---|---|

| Material Cost | Typically lower for thin paperboard | Higher due to multi-layer structure |

| Printing Options | Offset, digital, high-res, premium finishes | Flexo is common, or litho-laminated for detail |

| Finishing Options | Lots: foil, embossing, spot UV, windows, die-cuts | More basic, but can add inserts & custom flutes |

| MOQ (Minimum Order) | Lower starting volume possible | Often higher to justify setup costs |

| Turnaround Time | Faster for small runs | May take longer for custom die-cut or lamination |

| Assembly & Labor | Can be pre-glued, easy for hand assembly | May need taping, strapping, extra reinforcement |

Quick Takeaway

- Folding cartons are cost-effective for retail-ready packaging with lots of printing options — even at smaller volumes.

- Corrugated boxes may cost more upfront but add serious protective value for shipping and bulk handling.

- Always check how your supply chain handles storage and assembly: the wrong box can eat up labor costs fast!

Sustainability & Recycling Factors

Today’s brands can’t ignore sustainability — and your packaging choice plays a big part. Here’s how folding cartons and corrugated boxes stack up when it comes to eco-friendliness:

| Aspect | Folding Carton | Corrugated Box |

|---|---|---|

| Material Source | Often made with virgin or recycled paperboard | Commonly made from high-recycled-content kraft paper |

| Recyclability | 100% recyclable if free from plastic laminates or foil | Highly recyclable; corrugated fiber is a recycling champ |

| Biodegradability | Breaks down quickly; thin board decomposes faster | Heavier but still naturally biodegradable |

| Sustainability Creds | FSC-certified options available; good for retail branding | FSC-certified kraft linerboard; strong consumer trust |

| Reuse Potential | Limited reuse — more single-use | Strong enough for reuse, especially for shipping |

Quick Takeaway

- Both options score high on recyclability, but corrugated boxes often win for reusability — they’re tough enough to get a second or third life.

- If your product is going for premium finishes, remember: foil or plastic lamination on folding cartons can reduce recyclability.

- Keep an eye on certifications like FSC to boost your sustainability marketing.

Real-World Use Cases: Which Industries Prefer Which?

Understanding who uses what — and why — makes it easier to choose the right solution for your own products. Let’s look at some practical industry examples.

When Folding Cartons Are the Star

- Retail Packaging — From cosmetics to pharmaceuticals, folding cartons shine on shelves. Their smooth surface and printability make them ideal for vibrant branding and small retail items like perfumes, beauty serums, and supplements.

- Food & Beverage — Think cereal boxes, frozen meals, tea packaging — lightweight yet protective, perfect for high-volume consumer goods.

- Electronics Accessories — Small gadgets, phone accessories, or earphones often come in folding cartons to show off branding and provide an upscale unboxing feel.

When Corrugated Boxes Take Over

- E-Commerce Shipping — Subscription boxes, mailer boxes, and protective shipping cartons use corrugated because it can handle rough handling in transit and stacking in warehouses.

- Heavy or Bulky Items — Appliances, bulk food shipments, or multiple-item kits are better protected by sturdy corrugated boxes.

- Retail Displays — Custom-printed corrugated POP displays and dump bins stand up to daily wear on shop floors while still looking polished.

Blended Solutions

Don’t forget: Many brands use both. It’s common to pack luxury items in a printed folding carton and then place that carton inside a protective corrugated shipping box for safe delivery.

Key Takeaway: Your choice depends on the journey — is your product just sitting pretty on a shelf, or does it need to survive the shipping gauntlet? Align your material with your customer’s expectations for both presentation and protection.

Cost, MOQ & Lead Time Comparison

Understanding the true cost of your packaging choice goes far beyond just the price per box. It’s about balancing unit cost, order flexibility, and turnaround times — all of which can impact your bottom line.

Folding Cartons: Generally Cost-Effective for High Volumes

- Cost per Unit: Lower material weight and simple die-cutting make folding cartons more affordable when ordered in bulk. Perfect for large production runs like seasonal retail products.

- Minimum Order Quantities (MOQs): Often higher than corrugated for offset printing to be economical — think thousands of units to get the best price per piece.

- Lead Time: Fast to produce and ship because the material is lightweight and runs efficiently through die-cutters and printers. Average lead time can be 2–4 weeks once artwork is approved.

Corrugated Boxes: More Costly per Unit, but Flexible

- Cost per Unit: Corrugated boxes use more material and layers, so they’re usually a bit pricier per box, especially if you’re adding high-end printing like litho lamination.

- Minimum Order Quantities: MOQs can be more flexible, especially with digital printing options. This makes corrugated boxes popular for startups or subscription boxes that test new designs.

- Lead Time: Production can take slightly longer due to more complex structure and finishing steps. Expect 3–5 weeks for custom orders, especially for large or multi-piece designs.

Quick Tip

Always ask your supplier about cost-saving design tweaks — like combining multiple SKUs into one box size, or optimizing your dieline to use less board. Small changes can mean big savings!

Sustainability Factors: Which Is Greener?

In today’s market, you can’t ignore how your packaging choices affect both the environment and your brand’s reputation. So, which is the better option when it comes to sustainability — folding cartons or corrugated boxes?

Folding Cartons: Light but Limited in Recycling Cycles

- Material Impact: Folding cartons are often made from SBS (solid bleached sulfate) or recycled paperboard. They’re lightweight, which helps reduce shipping emissions.

- Recyclability: They’re generally easy to recycle, but if they’re heavily coated with laminates or metallic foils, that can reduce recyclability.

- Lifecycle: Because they’re thinner and sometimes laminated, folding cartons may have a shorter reuse and recycling life compared to corrugated.

Good to know: Brands that sell premium or cosmetic products often highlight FSC-certified or post-consumer recycled board on their packaging to boost sustainability credentials.

Corrugated Boxes: A Recycling Champion

- Material Impact: Corrugated boxes are the most recycled packaging material worldwide. Made with kraft liners and fluted medium, they’re durable and can be reused multiple times.

- Recyclability: They’re easily recyclable, even if printed in full color. Many corrugated options now use high percentages of recycled fiber.

- Lifecycle: Stronger structure means they’re often reused before being recycled, giving them a longer lifespan.

Brand Tip: Many e-commerce brands use messaging like “Please Recycle” or custom printing inside boxes to remind customers they’re part of a sustainability loop.

Final Takeaway

Whether you pick folding cartons or corrugated, choosing responsibly sourced materials and working with suppliers who hold certifications (like FSC or PEFC) helps meet your customers’ growing demand for eco-friendly packaging.

Practical Design & Branding Tips for Each Box Type

Whether you choose folding cartons or corrugated boxes, the design stage is where your packaging transforms from just a container into a real extension of your brand story. Here’s how to get the most out of each packaging type.

1. Folding Cartons: How to Elevate Lightweight Retail Packaging

Folding cartons are a top choice for retail products that need shelf appeal and a premium look — think cosmetics, supplements, and luxury foods.

Tips to maximize impact:

- Use vibrant, high-quality printing: Take advantage of the smooth paperboard surface to showcase detailed graphics and vivid colors.

- Add special finishes: Spot UV, foil stamping, embossing, and debossing add tactile interest and perceived value — perfect for premium positioning.

- Keep it clean: Smart use of negative space and minimalist design can convey sophistication and avoid clutter.

- Include structural add-ons: Inserts and custom-fit trays not only protect fragile items but also enhance the unboxing experience.

- Highlight sustainability: Clearly communicate any FSC certification or recyclability info to connect with eco-conscious consumers.

2. Corrugated Boxes: Design Ideas for Shipping That Builds Brand Loyalty

Corrugated boxes are known for durability and shipping protection, but with clever design, they can do so much more than protect products in transit.

How to make your corrugated packaging work harder:

- Maximize surface area: Use large logos, bold colors, or playful illustrations on the outer flaps — they’ll stand out on the doorstep.

- Inner print details: Surprise customers with messaging or graphics printed inside the box to create a memorable unboxing moment.

- Functional cues: Add clear handling instructions, fragile icons, or sustainability messages to build trust and professionalism.

- Protective inserts: Custom dividers or cushioning improve product safety and help with organized presentation, especially for sets.

- Reusable closures: Consider easy-open tear strips, Velcro, or resealable adhesive strips to encourage reuse and keep your packaging top-of-mind.

3. Universal Design Principles for Both

Regardless of which type you choose, always remember these cross-category best practices:

- Precision sizing: Well-measured boxes minimize wasted space, cut down on shipping costs, and protect your products better.

- Consistent branding: Fonts, colors, and logos should match your overall brand identity for a seamless omnichannel experience.

- Test before you launch: Always request physical samples to check print accuracy, structure, and finishing quality before full production.

- Promote your green efforts: Whenever possible, choose recyclable, compostable, or certified sustainable materials — and say so clearly.

By combining thoughtful design with functional structure, your folding cartons or corrugated boxes will do more than carry your product — they’ll strengthen your brand story and keep customers coming back.

Industry Applications & Real-World Use Cases

Understanding how other businesses use folding cartons and corrugated boxes can help you spot opportunities to improve your own packaging strategy. Let’s break down where each type shines — and what you can learn from real-world examples.

Folding Cartons: Trusted in Retail & Shelf-Ready Packaging

Folding cartons are everywhere in retail, thanks to their light weight and custom print possibilities. Industries that benefit most include:

- Cosmetics & Personal Care: Think of a high-end perfume or skincare box with foil stamping and spot UV. The elegant look helps justify premium pricing and makes the product stand out on crowded shelves.

- Food & Beverage: Folding cartons are popular for dry foods like cereals, tea boxes, or confectionery packaging. They allow for vibrant branding, easy opening, and resealability.

- Pharmaceuticals: Small, tamper-evident folding cartons are perfect for medicine and supplements, providing enough surface for mandatory information and dosage details.

- Luxury Goods & Gifts: Rigid-style folding cartons with magnetic closures or ribbon pulls elevate the customer experience for jewelry, candles, or seasonal gift sets.

Real-world inspiration: Many boutique chocolate brands use folding cartons with unique die-cut windows to give a sneak peek of the treats inside, building anticipation without compromising protection.

Corrugated Boxes: E-commerce, Subscription & Bulk Shipping Heroes

Corrugated packaging is the backbone of e-commerce and wholesale logistics because it combines durability with cost efficiency. It’s a top pick for:

- Online Retail & Subscription Boxes: From beauty subscription kits to custom apparel shipments, corrugated boxes protect products during long transits and multiple handling stages.

- Electronics & Appliances: Fragile or high-value products like laptops or kitchen gadgets rely on double-wall corrugated boxes with custom inserts for extra shock absorption.

- Heavy Consumer Goods: Items like bulk groceries, home goods, or sports equipment often require reinforced fluting and larger box dimensions to handle weight and stacking.

- Display-Ready Packaging: Retail-ready corrugated trays or shippers allow easy shelf placement at big-box stores, saving time and labor costs.

Real-world inspiration: Subscription brands like meal kits often use custom-printed corrugated boxes with colorful inner graphics and QR codes to enhance unboxing and drive repeat purchases.

Blending Both: Multi-Material Solutions

Some brands smartly combine folding cartons and corrugated packaging for layered protection and branding:

- Premium candles, for example, may come in an embossed folding carton that slides neatly into a sturdy corrugated mailer for shipping.

- Retail display units often use a corrugated base for structure with folding carton inserts to showcase individual SKUs.

Key takeaway: Knowing how these industries match packaging types to product needs can inspire you to choose the right material, structure, and branding techniques for your own offerings.

Tips for Choosing the Right Box for Your Business

Choosing between folding cartons and corrugated boxes isn’t just about picking a material — it’s about balancing durability, cost, branding, and your product’s journey from warehouse to customer. Here are some actionable tips to help you make the right decision.

1. Understand Your Product’s Weight and Fragility

If you’re packaging delicate or heavy items, corrugated boxes offer the structural strength and shock absorption you need. On the other hand, for lightweight, non-fragile goods — like snacks, cosmetics, or small gifts — folding cartons often get the job done while adding a premium retail feel.

Pro Tip: Run drop tests on prototypes. Simulate your actual shipping route to see how your packaging holds up during transit.

2. Match Packaging to Your Sales Channel

Are you shipping direct-to-consumer via e-commerce? Corrugated mailer boxes with custom inserts might be your best bet for protection and a memorable unboxing. For items that go straight onto retail shelves, folding cartons with sharp, eye-catching graphics will help your product compete for attention.

3. Factor in Branding and Printing Needs

Folding cartons generally offer better printability for detailed designs, high-end finishes like foil stamping or embossing, and vibrant colors. Corrugated boxes can also be branded inside and out — but remember that complex artwork may require premium techniques like litho-lamination.

4. Consider Sustainability Goals

If sustainability is central to your brand, communicate that through your packaging choice. Both materials are recyclable, but many buyers love seeing FSC-certified paperboard or post-consumer recycled content. Eco-friendly inks, minimal coatings, and clever structural design can reduce material use and boost your green credentials.

5. Don’t Forget Practical Details

- Storage & Assembly: Folding cartons arrive flat and save space but need folding and gluing. Corrugated boxes are bulkier but easier to handle for large shipments.

- Minimum Order Quantities (MOQs): Complex print jobs or custom die-cuts might require higher MOQs. Always check with your packaging supplier early to avoid surprises.

- Cost vs. Protection: Higher upfront packaging costs can actually save you money if they reduce returns and damaged goods.

6. Work with a Trusted Packaging Partner

An experienced manufacturer can help you compare samples, recommend inserts or coatings, and find the right balance between cost and quality. Don’t hesitate to ask for structural prototypes — seeing and testing them is worth every penny.

Final Tip: Always Think Customer Experience

Whether it’s the premium feel of a rigid folding carton on a boutique shelf or the durability of a branded corrugated box arriving at someone’s doorstep, great packaging does more than protect a product — it tells your brand story and keeps your customers coming back.

Ready to Choose the Right Packaging? Let’s Make It Happen

Still deciding between folding cartons and corrugated boxes? You don’t have to figure it out alone. Our experienced team is here to help you compare options, design custom solutions, and ensure your packaging protects your products and tells your brand story beautifully.

Reach out today to get tailored recommendations, request prototypes, or get a free quote — and let’s build packaging that works as hard as you do.

Table of Contents