Custom Battery Packaging: Ultimate Guide to Innovative & Safe Solutions

Introduction to Custom Battery Packaging

In today’s fast-paced, technology-driven world, batteries power nearly everything we touch—smartphones, electric cars, laptops, medical equipment, and even spacecraft. Yet behind every battery lies an often-overlooked hero: the packaging. Custom battery packaging not only ensures safe storage and transportation but also plays a vital role in branding and sustainability. With the rise of high-energy lithium-ion batteries and the global push for greener solutions, custom battery packaging is no longer optional—it’s essential.

Why Battery Packaging Matters in Modern Industries

Batteries are sensitive, high-energy components. A poorly designed package can lead to overheating, leakage, or even explosions. Custom packaging reduces these risks while protecting products during shipping and handling. Moreover, packaging is the first thing consumers see, making it a crucial touchpoint for brand identity.

The Rise of Customization in Packaging

Gone are the days of generic plastic casings. Companies now seek tailored solutions that balance safety, design, and environmental impact. From recyclable materials to smart sensors that track battery health, customization is reshaping the packaging industry.

Understanding Battery Packaging Basics

What is Custom Battery Packaging?

Custom battery packaging refers to specialized enclosures designed to fit, protect, and present batteries according to unique product requirements. Unlike one-size-fits-all options, custom packaging considers battery type, size, usage environment, and branding needs.

Types of Batteries That Require Packaging

Different batteries require different levels of care:

Lithium-ion batteries

Common in smartphones, laptops, and EVs, lithium-ion batteries demand strict packaging due to their high energy density and flammability risk. Packaging often includes shock absorption, flame-resistant liners, and temperature control features.

Lead-acid batteries

Heavier and bulkier, lead-acid batteries—often used in vehicles and backup power systems—require robust, corrosion-resistant packaging.

Alkaline and rechargeable batteries

These everyday batteries are usually packaged in blister packs, cardboard boxes, or eco-friendly alternatives for retail display.

Key Features of Custom Battery Packaging

Durability and Safety

Packaging must withstand mechanical stress during handling and transport while preventing short circuits and leakage.

Temperature Resistance

Batteries are highly sensitive to heat. Packaging materials should provide insulation against extreme temperatures.

Shock Absorption and Anti-Leak Protection

Foam inserts, layered barriers, and leak-proof seals safeguard batteries from impact and potential chemical leaks.

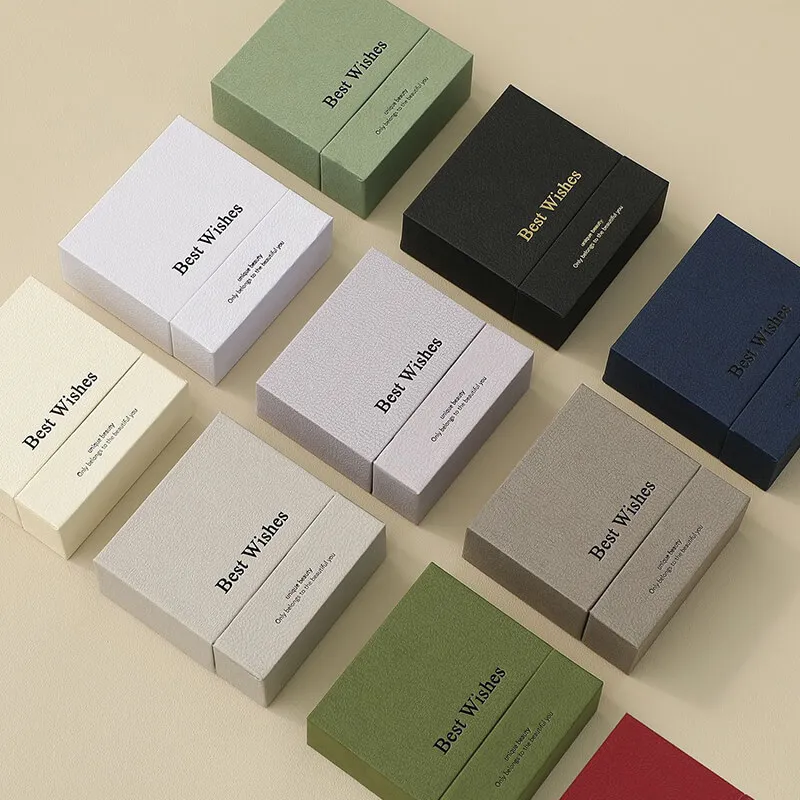

Branding and Aesthetic Design

Beyond safety, packaging doubles as a marketing tool. Logos, colors, and creative layouts help products stand out in crowded markets.

Materials Used in Custom Battery Packaging

Cardboard and Paperboard

Lightweight, recyclable, and affordable—perfect for retail packaging.

Plastic and Thermoplastics

Durable and moisture-resistant, plastics are widely used but face sustainability challenges.

Metal and Hybrid Packaging

Aluminum and steel provide premium protection, especially for industrial batteries. Hybrid solutions combine materials for enhanced performance.

Design Innovations in Battery Packaging

Smart Packaging with QR Codes and Sensors

Innovation has taken packaging far beyond cardboard and plastic. Smart packaging integrates technology, enabling real-time monitoring of batteries during transport. QR codes allow consumers to verify authenticity, while embedded sensors track temperature, humidity, and shock levels. This reduces risks during shipping and builds customer trust.

Eco-Friendly and Sustainable Packaging Options

With sustainability becoming a priority for both brands and consumers, eco-friendly packaging is in high demand. Manufacturers are exploring biodegradable materials, recycled cardboard, and plant-based plastics. Sustainable design not only minimizes environmental impact but also enhances a company’s reputation in green markets.

Compact and Lightweight Packaging Trends

Space is money in logistics. Companies are leaning toward compact, lightweight packaging that reduces shipping costs without compromising safety. Advances in material science make it possible to achieve both efficiency and strength in packaging design.

Industry Applications of Custom Battery Packaging

Consumer Electronics

From smartphones to laptops, consumer electronics rely heavily on lithium-ion batteries. Packaging must be sleek, lightweight, and retail-friendly, balancing safety with aesthetic appeal.

Automotive and Electric Vehicles

Electric vehicles (EVs) use massive lithium-ion battery packs that demand highly specialized packaging. These solutions focus on thermal management, fire resistance, and structural integrity to ensure passenger safety and compliance with strict regulations.

Medical Devices

Pacemakers, hearing aids, and portable diagnostic equipment use small but critical batteries. Custom packaging in this field prioritizes sterile, tamper-proof, and easy-to-handle designs.

Aerospace and Defense

High-performance batteries for satellites, drones, and military equipment require packaging that withstands extreme conditions such as pressure changes, vibrations, and high altitudes. Failure in this sector can be catastrophic, making custom solutions indispensable.

Regulations and Standards for Battery Packaging

UN and DOT Regulations for Transport

Transporting batteries, especially lithium-ion types, is tightly regulated by international bodies like the United Nations (UN) and the U.S. Department of Transportation (DOT). Guidelines specify how batteries should be packaged to prevent accidents during shipping by air, land, or sea.

Industry Safety Certifications

Beyond transportation, certifications such as IEC 62133 and UL standards ensure that packaging complies with safety, performance, and environmental benchmarks. Companies must work with certified suppliers to meet these global standards.

Benefits of Custom Battery Packaging

Enhanced Safety and Protection

Safety is the number one priority. Custom packaging prevents short circuits, leaks, and thermal runaway, protecting not just the battery but also the end user.

Brand Recognition and Customer Appeal

Unique packaging design gives companies a competitive edge. Branded packaging reinforces identity and creates memorable unboxing experiences, especially in retail electronics.

Cost-Effectiveness Over Time

While custom packaging may seem more expensive upfront, it reduces long-term costs by minimizing product returns, shipping damages, and compliance fines.

Choosing the Right Custom Battery Packaging Supplier

Key Factors to Consider

When selecting a supplier, businesses should consider:

- Experience with battery-specific packaging

- Compliance with international safety standards

- Range of sustainable material options

- Design and branding capabilities

Questions to Ask Before Partnering

- Do you comply with UN, DOT, and IEC regulations?

- What sustainable materials can you provide?

- How do you test packaging for durability and safety?

- Can you integrate branding elements into the design?

Future Trends in Custom Battery Packaging

Smart Packaging Integration

The future lies in connected packaging—systems that provide real-time tracking of temperature, pressure, and location during transit. IoT (Internet of Things) technology will make packaging part of the digital supply chain.

Biodegradable and Recyclable Packaging

Eco-conscious consumers are pushing brands toward biodegradable and recyclable packaging. Expect to see more innovations in plant-based plastics, molded pulp, and reusable shipping containers.

Automation in Packaging Design

Robotics and AI are making packaging faster, smarter, and more cost-efficient. Automation reduces human error and speeds up production while maintaining consistency in safety standards.

FAQs About Custom Battery Packaging

Q1. Why is custom battery packaging important?

Custom battery packaging ensures safety during shipping, storage, and use while also helping brands stand out in competitive markets.

Q2. What materials are commonly used in custom battery packaging?

Common materials include cardboard, plastics, metal, and hybrid designs, depending on the battery type and industry application.

Q3. Is custom packaging more expensive than standard packaging?

While initial costs are higher, custom solutions often reduce long-term expenses by preventing damage and regulatory fines.

Q4. How does custom battery packaging improve safety?

It includes features like shock absorption, thermal insulation, anti-leak barriers, and compliance with international safety standards.

Q5. Can battery packaging be eco-friendly?

Yes, companies are adopting sustainable materials such as recycled cardboard, biodegradable plastics, and reusable packaging systems.

Q6. Which industries benefit most from custom battery packaging?

Industries like consumer electronics, automotive, medical devices, and aerospace heavily rely on custom solutions for safety and performance.

Conclusion

Custom battery packaging is more than a protective shell—it’s a critical element of safety, branding, sustainability, and innovation. As batteries become increasingly central to our lives, from powering electric cars to life-saving medical devices, the importance of well-designed packaging cannot be overstated. Looking ahead, the integration of smart technology, eco-friendly materials, and automation will continue to redefine what’s possible. Businesses that invest in innovative custom battery packaging today will not only protect their products but also strengthen their brand for the future.

Table of Contents