Blank cardboard cigarette boxes are a low-friction path to compliant, brand-ready packaging. You control unit cost, reduce environmental impact, and accelerate time-to-market. For European and North American buyers, this is where sustainable materials, print flexibility, and tight supply chain execution intersect. POZI Packaging delivers OEM/ODM solutions that translate design intent into scalable production—without drama.

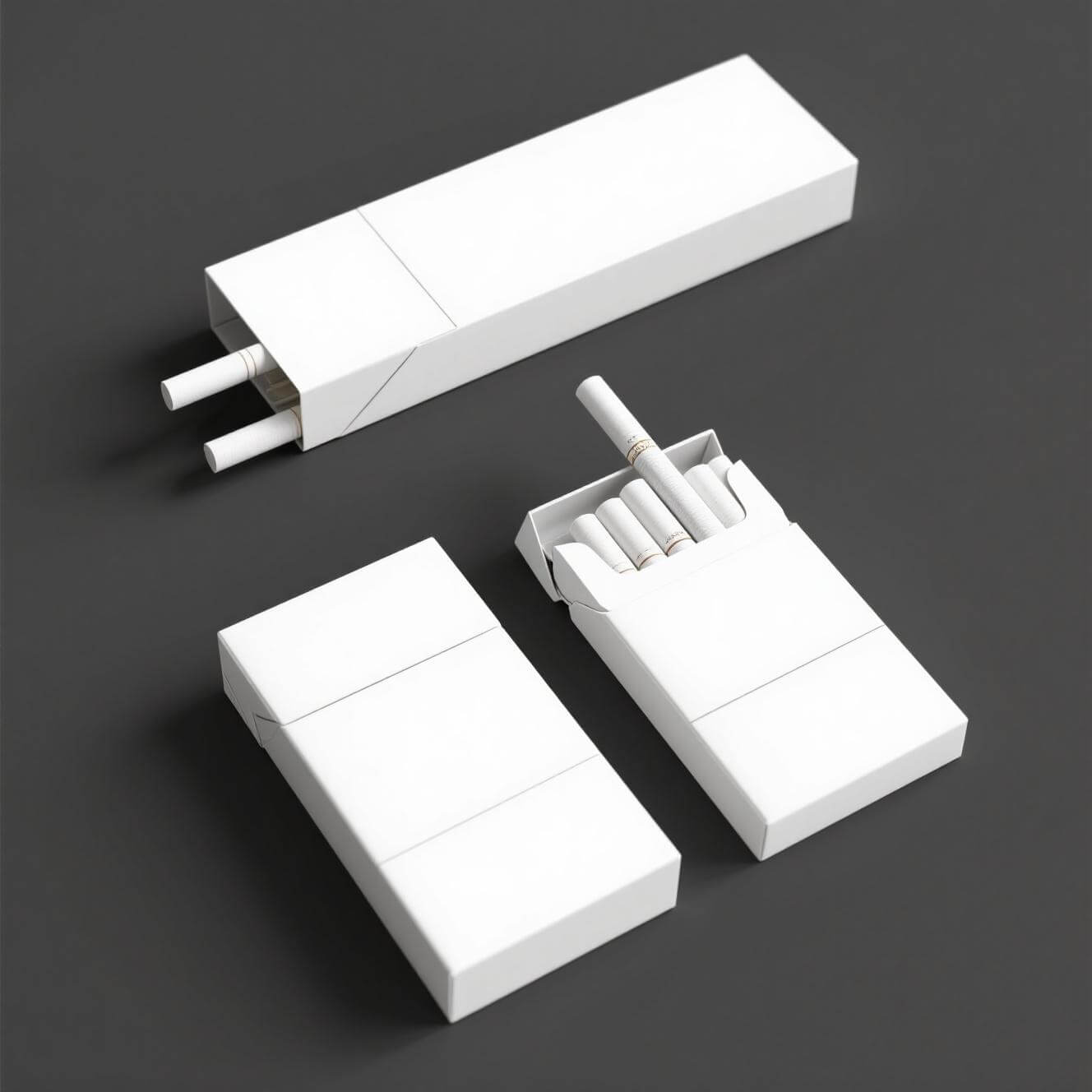

What Exactly Is a “Blank Cardboard Cigarette Box”?

A blank cardboard cigarette box is an unprinted, brand-agnostic paperboard structure designed as a clean canvas for later customization. It typically features:

- Board types: SBS, coated recycled board, or kraft back options—selected for stiffness, print fidelity, and sustainability targets.

- Purpose: Protect sticks from compression, humidity, and light while meeting retail, handling, and regulatory display needs.

- Why “blank” helps: Standardized base construction simplifies procurement, while graphics, finishes, and mandatory markings get layered on when your artwork and market claims are finalized.

Core Advantages (Function → Benefit → Outcome)

- Eco Profile → Recyclable fiber + mono-material builds → Meets retailer and brand ESG targets and improves shelf acceptance.

- Cost Efficiency → Optimized board grade and caliper → Lower material spend and improved cube utilization across freight lanes.

- Brand Flexibility → Blank base + modular finishing → Rapid line extensions and market-specific labeling without resetting structural inventory.

- Protection & Performance → Rigid geometry + precise die-cut → Reduced crush risk, consistent open/close feel, fewer returns.

- Regulatory Readiness → Space for warnings, age marks, disposal icons → Compliance-friendly layouts across multiple jurisdictions.

Structural & Finishing Options That Actually Move the Needle

- Structures: Hinge-lid hard pack; soft pack shells (on request); tear-tape integration; inner frame fit.

- Board & Caliper: Selected to balance stiffness vs. weight, maintain crease integrity, and protect edges in transit.

- Printing (when you’re ready): Offset or digital for short runs; spot colors for brand accuracy; water-based or low-VOC inks.

- Finishes: Matte/gloss varnish or lamination, foil accents, emboss/deboss, tactile coatings—applied selectively to protect recyclability.

- Overwrap & Liners: Film overwrap (where required), inner barrier liners aligned with local regulations and recyclability guidance.

How POZI Packaging Delivers (Process You Can Run on Repeat)

- Brief & Dieline Alignment

We capture format, sticks-per-pack, mandatory marks, and logistics constraints. You receive a press-ready dieline and a packaging checklist to prevent rework.

- Material Selection & Prototyping

We propose board options with sustainability notes and run a structural prototype to validate fit, rigidity, and crease behavior.

- Print & Finish Plan

For blanks: we lock structure and supply. For branded runs: we align color targets, finishes, and warning panel hierarchies.

- Pilot to Scale

Short pilot to test line speed and QC gates, then scale to volume with multi-point inspections at cutting, folding/gluing, and final packout.

- Logistics Playbook

Master carton engineering, pallet patterning, moisture controls, and export docs prepared for your lanes.

Commercials at a glance:

- Typical MOQ: 1,000 units (flexible by format).

- Lead Time: ~15–30 days after approval; samples usually faster.

- Service: Free structural consultation; fast response within hours; damage-loss support aligned with your terms.

Sustainability Playbook (Practical, Not Performative)

- Material: FSC-capable sources, recycled content options, and mono-material builds that actually recycle.

- Inks & Coatings: Water-based varnish or low-migration systems; selective foil to preserve fiber recovery.

- Design for Recycling: Avoid mixed substrates unless mandated; rationalize finishes to keep repulpability high.

- Lightweighting: Right-size board caliper to cut grams per unit without compromising pack integrity.

- Supply Chain: Batch planning and consolidated shipments to lower transport emissions per 10k units.

Cost Engineering — Where Savings Really Come From

- Board Grade & Caliper Tuning: Match stiffness to route risk (stack height, clamp handling) to reduce over-spec.

- Format Standardization: Share a single structure across SKUs; differentiate via print and labels.

- Cartonization & Pallet Density: Maximize packs per master carton; align pallet patterns with your carriers’ sweet spots.

- Make-Ready Efficiency: For branded runs, ganged artwork and shared finishing plates cut setup times.

- Waste Reduction: Tighter die-cut nesting and trim recovery lower cost per thousand.

Risk & Quality Controls (So You Don’t Pay for Surprises)

- Die-Cut Consistency: Clean edges, stable creases, and hinge performance validated on pilot.

- Color Discipline (when printed): Clear brand books, drawdowns, and measurable tolerance targets.

- Humidity Management: Storage guidelines and transport protections reduce warp and curl.

- Documentation: COA/TDS on request; export paperwork aligned with destination requirements.

- Final Inspection: AQL-based sampling with photographic evidence and pack-out shots.

Market Outlook — What Buyers Should Plan For

- Regulatory Tightening: Space allocation for warnings and responsible disposal icons is non-negotiable; plan artwork layers early.

- ESG & Retail Pressure: Recyclable mono-material packs and simplified finishes gain shelf access and consumer trust.

- Short-Run Agility: Digital print unlocks compliant micro-variants without bloating inventory.

- Supply Chain Resilience: Dual-sourcing materials and standardized dielines reduce downtime when lanes get noisy.

FAQ

Q1. Why choose blank boxes first?

To lock structure, run pilots, and keep inventory flexible while artwork is finalized for each market.

Q2. Can you hit strict sustainability targets?

Yes. We support recycled content, FSC options, water-based coatings, and mono-material designs that are actually recoverable.

Q3. What drives unit cost the most?

Board grade/caliper, finishes, print passes, and pallet density. We optimize these without compromising protection.

Q4. How fast can I get samples?

Structural samples are typically quick once dielines are approved. Branded samples depend on finish complexity.

Q5. Do you support multiple warning panel versions?

Yes. We manage artwork variants and label sets by market while keeping the base structure identical.

Q6. What about overwraps and liners?

We supply where required and advise on recyclability impact by region.

Q7. Minimum order & lead time?

Typical MOQ ~1,000 units; standard lead 15–30 days after approvals.

Q8. Can you co-engineer master cartons?

Absolutely. We design master cartons and pallet patterns to minimize damage and freight spend.

Make Your Next Run Boringly Predictable

Bring us your pack format, warning requirements, and lane constraints. POZI Packaging will deliver a dieline, a structural sample, and a clean plan from pilot to scale—so your next launch is on-spec, on-time, and on-cost.