Upgrade Your Brand & Launch Faster

Executive angle: This is not a catalog of what we can make. It’s a playbook of what you will achieve—sharper brand perception, higher conversion, lower returns, and reliable launches—using proven structures, materials, and finishes that the jewelry industry trusts.

What you actually get

- Brand lift on day one. Premium visual and tactile cues that align store displays and hero images online.

- Higher conversion via better unboxing. Layered structures, clean reveal moments, and camera-ready details that increase “add-to-cart,” reviews, and UGC.

- Fewer returns and breakages. Rigid-box engineering plus dual-box shipping systems that stand up to long-haul logistics.

- Faster new-SKU cycles. Standard die libraries and three-tier options that compress sample and production lead times.

- Premium feel within target budget. Spend where perception peaks—logo & touch—without inflating total landed cost.

Use-case playbook

1) E-commerce shipping protection + unboxing

Result you get: Lower damage/return rates and a photogenic reveal that feeds reviews and social content.

How we do it: Drawer or book-style rigid box + EVA/velvet insert + dedicated corrugated mailer (dual-box set). Drop/edge/crush tests in sampling.

Budget tiers:

- Standard: 1.5–2.0 mm board, single-point foil, generic mailer.

- Enhanced: 2.0–2.5 mm board, EVA molded insert, custom mailer.

- Flagship: 2.5–3.0 mm board, anti-rattle geometry, velvet overlay, concealed magnets.

Metrics to watch: Damage rate, return rate, UGC video completion.

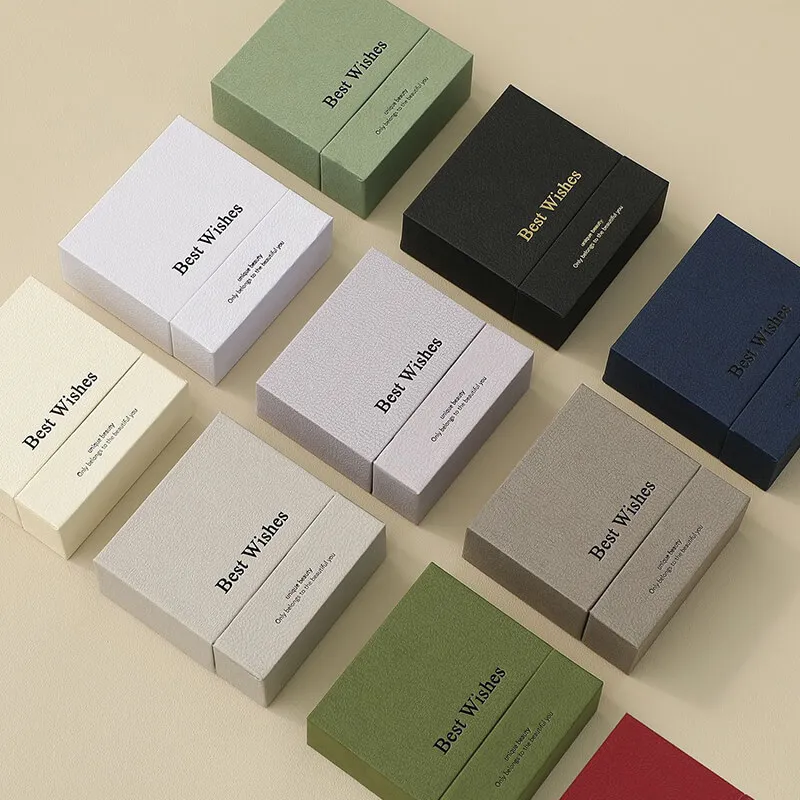

2) Store merchandising & brand upgrade

Result you get: Immediate “premium” read on shelf and at the counter; higher pick-up and trial rates.

How we do it: Leather-grain or uncoated tactile papers + champagne/rose-gold foil + deboss; coordinated trays and display cards.

Budget tiers:

- Standard: PMS + matte film.

- Enhanced: Add foil or deboss.

- Flagship: Foil × deboss combo, leather-grain wrap, velvet insert.

Metrics to watch: Try-on rate, average ticket, ΔE color tolerance adherence.

3) Promotions & volume efficiency

Result you get: Scale events (Valentine’s, Mother’s Day, Christmas) without cost spikes.

How we do it: Lightweight lid-and-base or foldable paperboard; high pack-out and fast plate changes.

Tactics: Colored kraft/black-core with single-point foil; optional belly band for a quick “visual lift.”

4) High protection (watches, sets, precious metals)

Result you get: Display-worthy stiffness and shipping safety for higher-value ensembles.

How we do it: 2.5–3.5 mm board + watch pillow or precision insert; book or drawer style; anti-scuff lining.

5) Low MOQ, rapid newness (studios & micro-brands)

Result you get: Frequent drops with consistent brand feel.

How we do it: Standard die + variable paper/foil palette; lean sampling SLA.

Practical mix: Uncoated tactile paper + single foil; add a belly band when you need a quick edition refresh.

6) Compliance & ESG passes first time

Result you get: Retail and marketplace acceptance without rework.

How we do it: FSC/recycled stocks, water-based inks, plastic-free inserts on request; recyclable marks and ready-to-use declarations.

Material & finish library

Rigid board thickness ranges

Thickness drives hand-feel and crush resistance; it also impacts cartonization and freight. Tolerances ±0.1–0.2 mm are typical.

| Application | Typical structures | Standard | Enhanced | Flagship | Notes |

|---|---|---|---|---|---|

| Ring/ear studs | Lid-and-base / Drawer | 1.5 mm | 1.8 mm | 2.0 mm | Standard is stable; flagship supports heavy finishing. |

| Necklace/bracelet | Drawer / Book | 1.8 mm | 2.0 mm | 2.5 mm | 2.0 mm is the workhorse. |

| Gift sets | Book / Magnetic | 2.0 mm | 2.5 mm | 3.0 mm | Ceremony feel + display stiffness. |

| Watch box | Book / Drawer | 2.5 mm | 3.0 mm | 3.5 mm | Add pillow and anti-rattle forms. |

| E-com dual-box | Rigid + mailer | 1.8–2.0 mm | 2.0–2.5 mm | 2.5–3.0 mm | Pair with tailored mailer for lowest breakage. |

Engineering tip: Pair thicker boards with appropriate wrap weights; pre-crease and corner skive to avoid wrinkling on tight radii.

Specialty papers (style × cost × process compatibility)

| Class | Visual & haptics | Finish pairing | Typical wrap weight | Cost band | Best for |

|---|---|---|---|---|---|

| Leather-grain (Saffiano/Lichee/Cross) | Clean, durable, fingerprint-resistant | Foil, deboss, blind-emboss | 120–160 gsm | Mid | Everyday premium |

| Uncoated tactile | Dry, soft-touch, matte | Foil, deboss, high contrast spot UV | 120–160 gsm | Mid | Minimal + premium |

| Linen/cloth-texture | Natural, understated | Foil, blind-emboss | 120–160 gsm | Mid | Modern/natural lines |

| Flocked/velvet paper | Plush gift feel | Larger-area foil | 120–180 gsm | Mid-high | VIP/seasonal |

| Pearlescent | Fine sparkle, reflective | Small-area foil | 120–160 gsm | Mid | Weddings, holidays |

| Metallic/mirror | Strong metal sheen | Spot UV, controlled-temp foil | 120–157 gsm | Mid-high | High-impact displays |

| Colored kraft / black-core | High contrast, crisp edges | Foil, white ink | 120–160 gsm | Low-mid | Speed & value |

| Wood/stone/fiber looks | Visible texture | Foil, blind-emboss | 120–160 gsm | Mid-high | Thematic editions |

| Velvet cloth / PU leather wraps | Max tactile prestige | Foil (sample-prove), badge | Fabric cover | High | Flagships |

Design rule: Heavy textures don’t love hair-line logos. Keep minimum letter height ≥ 2.5–3.0 mm and stroke ≥ 0.25–0.3 mm.

Foil swatches that read “premium”

- Gold family: Gloss Gold, Matte Gold, Pale Gold, Champagne Gold, Rose Gold

Use when you want premium without glare. Champagne/Rose over leather-grain or uncoated papers is a reliable “quiet luxury.” - Silver family: Gloss/Matte Silver, Nickel

Pairs cleanly with black, deep navy, and greys for a modern/masculine line. - Copper family: Copper, Rose Copper

Warm and artisanal; ideal over wood/linen textures. - Black & White foils: High contrast, crisp identity; white foil shines on dark wraps.

- Specials: Holographic/Rainbow/clear capsules for seasonal “spark”—use sparingly to avoid visual noise.

Process hygiene: Large foil panels need release gaps; textured wraps prefer matte/Champagne/white foils to avoid cheap glare.

Design accelerators that move the needle

- Spend where eyes land first. Prioritize logo finish + paper haptics; reduce ink colors; add a belly band to refresh visuals without structural change.

- Layer the reveal. Drawer + ribbon pull + insert color contrast creates a predictable “pause” that reads premium on video.

- Standard dies, custom feel. Start from a proven die, vary wrap and foil; it’s how you launch faster without compromise.

Price & lead-time tiers

- Standard: Standard die + single finish (mono-ink or single-point foil). Fastest lead times; budget-friendly.

- Enhanced: Add deboss or spot UV or step up paper quality. Noticeable feel upgrade.

- Flagship: Multi-finish stack (foil × deboss × inserts), premium wraps, thicker boards. Showpiece for hero SKUs.

Indicative SLA: Samples 3–5 days; production 15–20 days (expedite options available).

Buyer-type × solution matrix

| Buyer profile | Primary job | Structure & insert | Paper/finish | Price band | Reorder cadence |

|---|---|---|---|---|---|

| DTC cross-border | Ship safely + unbox well | Drawer/Magnetic + EVA | Uncoated or leather-grain + 1–2 finishes | Mid | Fast top-ups |

| Chain retail | Display presence | Leather-grain rigid + trays | Champagne/Rose Gold foil + deboss | Mid-high | Quarterly |

| Regional distributors | Promo throughput | Light lid-and-base / foldable | Colored kraft + single finish | Low-mid | Large batches |

| Watch/jewelry sets | High protection | Book/Drawer + pillow | 2.5–3.5 mm board + understated foil | High | Seasonal slots |

Quality, compliance, and the hidden variables

- Color control: Triangulate paper swatch × foil swatch × PMS; lock ΔE thresholds before mass run.

- Structural testing: Documented drop, edge, and crush checks; retain samples per batch for traceability.

- ESG & market gates: FSC/recycled, water-based inks, plastic-free inserts on request; recyclable marks and ready-made declarations.

- Operations: Clear sampling/production windows, peak-season capacity plans, reorder SOPs, and pack-out transparency (cartonization & cube).

FAQ

How do I get “premium” on a fixed budget?

Concentrate spend on wrap feel + a single iconic logo move (e.g., Champagne foil or deep deboss). Add a belly band for editioning. Cut color count elsewhere.

How do I crush returns for long-haul e-com?

Rigid board ≥ 2.0 mm + tailored EVA + dedicated corrugated mailer. Validate with drop/crush checks; add anti-rattle geometry on heavy SKUs.

Can I do low MOQ without losing brand feel?

Yes. Use standard dies; vary paper/foil. Keep a consistent insert silhouette and color system across SKUs.

Which foils read most “expensive”?

Champagne Gold and Rose Gold over leather-grain or uncoated wraps. Pair with a subtle blind-emboss pattern for depth without glare.

Will specialty papers slow me down?

Some can. We carry equivalents to hold schedule; visual parity can be achieved with paper swaps + foil choice + a band or label.

How to brief us for a first-pass solution (5 inputs, no homework required)

- Use case: Ring / Necklace / Set / Watch / E-com dual-box

- Target feel & budget lane: Standard / Enhanced / Flagship

- Logo move: Foil color (e.g., Champagne/Rose/Matte Gold), Deboss/Spot UV preference

- Insert type: EVA, velvet overlay, pillow (watch)

- Speed & volume: Sample date, desired in-hand date, qty

We’ll provide a clear, backed recommendation—covering board thickness, wrap selection, foil choice, cartonization notes, and lead-time window—so your team decides on outcomes, not guesswork.

Table of Contents

- Upgrade Your Brand & Launch Faster

- What you actually get

- Use-case playbook

- Material & finish library

- Design accelerators that move the needle

- Price & lead-time tiers

- Buyer-type × solution matrix

- Quality, compliance, and the hidden variables

- FAQ

- How to brief us for a first-pass solution (5 inputs, no homework required)