Home - Cardboard Cake Boxes

Custom Cardboard Cake Boxes

Lock-Corner, Windowed & Custom Print

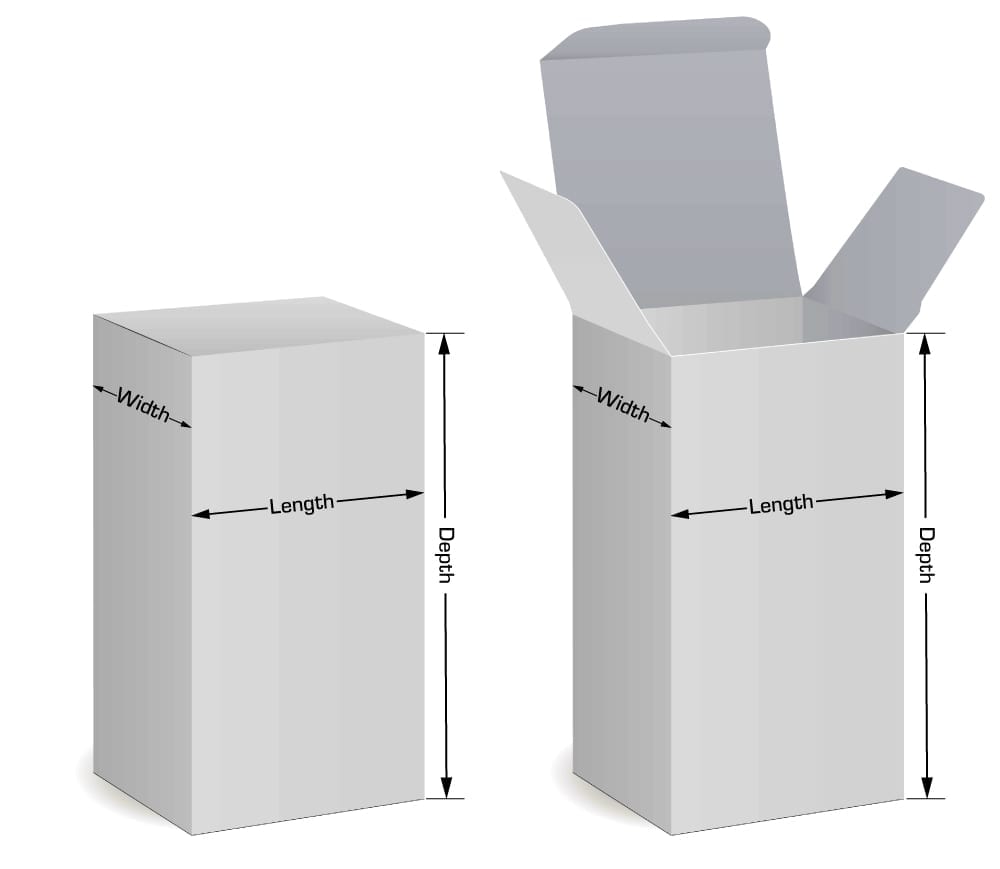

We manufacture cardboard cake boxes that assemble in seconds, protect finishes, and present your bakes beautifully. Choose one-piece lock-corner, lock & tab, or tall two-piece structures; specify standard 6–12″ size families or custom dielines; add window, color, and brand print. Boxes ship flat for efficient storage and fast counter assembly.

- Structures: lock-corner (one-piece), lock & tab, tall two-piece

- Sizes: 6–12″ families; common heights 2.5″ / 4″ / 5″ / 6″

- Options: window or non-window; white/kraft/colors; grease-resistant liners

- Execution: dielines on request; samples in 5–7 days; production 10–18 days; global delivery

| Category | Options (tunable) |

|---|---|

| Structures | One-piece lock-corner · Lock & tab · Two-piece (for tall cakes) |

| Standard sizes (in) | 6×6 · 7×7 · 8×8 · 9×9 · 10×10 · 12×12 (heights 2.5/4/5/6″) |

| Windows & colors | Window / Non-window · White / Kraft / Seasonal colors |

| Materials | SBS/C1S bakery board; kraft liners; optional grease-resistant coating |

| Printing & finishes | CMYK + Pantone; soft-touch / matte / gloss; foil; emboss/deboss; spot UV |

| Shipping & assembly | Ships flat · Fold & lock corners · Tool-free |

| Documentation | Dieline · Spec sheet · QC photos · Pack photos · Pallet map |

Size & Fit Matrix (cake → board → box)

| Cake diameter | Common board/drum | Recommended box (in) | Typical height |

|---|---|---|---|

| 6″ | 8″ board | 8×8×4 | 4″ |

| 7″ | 9″ board | 9×9×4 | 4″ |

| 8″ | 10″ board | 10×10×5 | 5″ |

| 9″ | 12″ board | 12×12×4/5 | 4–5″ |

| 10″ | 12″ board | 12×12×5/6 | 5–6″ |

| Tall/stacked | +2″ board | Two-piece tall | 6″ |

We also provide full metric specs and custom internal dimensions on request.

Styles & Windows

| Style | Use cases | Why choose it | Notes |

|---|---|---|---|

| Lock-corner (one-piece) | Daily retail, DTC | Fastest assembly; strongest corners; ships flat | Industry workhorse |

| Lock & tab | Gift presentation, color collections | Crisp edges; easy opening | Ideal for windowed variants |

| Two-piece (tall) | 6″ height, stacked or delicate décor | Lid/base stability; safer lifts | Often paired with corrugated base |

| Windowed | Shelf visibility, impulse buys | Clear product view; brand panel remains | PET or cellulose window |

| Non-windowed | Delivery, dark palettes | Maximum print area; best grease control | Label zones on matte panels |

Materials & Food-Contact Options

- Boards: bakery-grade SBS/C1S; kraft liners for natural look.

- Grease & moisture: optional grease-resistant coatings; specify target performance and claim language.

- Windows: PET or cellulose (plastic-free messaging); keep a matte label area adjacent to the window.

- Compliance: low-odor inks/adhesives; material statements supplied with samples (we execute your legal text; we do not provide legal advice).

Colors & Collections

- Core palettes: White / Kraft.

- Seasonal/brand sets: Pink / Blue / Black or Pantone-matched solids.

- Print kits: logo lockup, pattern, and back-panel story; interior lid printing available for care or QR journeys.

Assembly & Handling (counter-ready)

- Pop open the blank; fold & lock the corners.

- Load cake on board/drum; close lid (or place two-piece lid).

- Apply label to matte zone; stack per plan.

Time on counter: typically <15 seconds per box after training. Tools: none.

E-commerce & Wholesale Packouts

- Pack/Case guidance: we propose pack and master-case counts by size to optimize 3PL throughput.

- Pallet maps: supplied for standard footprints; DIM optimization available for courier routes.

- Photo packouts & QC checklists provided with each lot.

Printing & Finishes (brand-safe rules)

- Color control: CMYK + Pantone with ΔE targets across runs.

- Typography: reversed text ≥ 8 pt; minimum line 0.4–0.5 mm.

- Codes: barcodes/QR on matte panels with quiet zone ≥ 2.5 mm.

- Finishes: soft-touch (anti-scuff recommended for dark areas), matte/gloss lamination, foil, emboss/deboss, spot UV (kept off fold/label zones).

Technical Specifications (summary)

| Category | Spec (typical; tunable) |

|---|---|

| Structures | One-piece lock-corner · Lock & tab · Two-piece tall |

| Size families | 6×6 / 7×7 / 8×8 / 9×9 / 10×10 / 12×12 (heights 2.5/4/5/6″) |

| Boards | SBS/C1S bakery board; kraft options |

| Coatings | Grease-resistant (on request); soft-touch/matte/gloss finishes |

| Windows | PET or cellulose; anti-fog optional |

| Printing | CMYK + Pantone; interior lid print available |

| Tolerances | Panel ±1.0–1.5 mm; lid fit tuned to coating/lamination |

| Packaging | Flat-packed bundles; labeled master cases; pallet maps |

| Documentation | Dieline · Spec sheet · QC photos · Pack photos · Pallet map |

Sustainability

- Paper-first constructions for easy recycling (local rules apply).

- Cellulose window option for plastic-free narratives.

- Ship-flat design reduces transport volume.

- FSC-certified papers available on request.

MOQ, Sampling & Lead Time

- MOQ: typically 1,000–3,000 per size/color/structure

- Samples: 5–7 days (white dummy + printed proofs if required)

- Production: 10–18 days after approvals (finish/window dependent)

- Trade terms: FOB/CIF/DDP; consolidated pallets; global delivery

Why POZI

- Standardized size families + heights for fast SKU planning

- Lock-corner engineering for quick assembly and strong corners

- Window/non-window and color collections with brand-safe print rules

- Tight QC + photo packouts and pallet maps for frictionless receiving

- FSC options and recyclable builds end to end

FAQ

Can you match our brand color?

Yes—Pantone-matched solids with ΔE control across runs.

Do you offer tall boxes for stacked cakes?

Yes—two-piece constructions in 6″ height with reinforced corners or corrugated bases.

Can we add a window and keep a recyclable claim?

Use a cellulose window and paper-based boards; we align claim language with chosen materials.

Are the boxes grease-resistant?

Yes—specify a grease-resistant liner/coating where required.

How fast do they assemble in store?

One-piece lock-corner folds in seconds after training; no tape or tools.

What files do you need for artwork?

Vector AI/PDF, 3 mm bleed, outlined fonts, Pantone codes, and finish layers.