What Is a Corrugated Box?

Corrugated boxes are engineered packaging solutions built for strength, durability, and product protection—making them the backbone of global logistics and e-commerce shipping.

Unlike simple cardboard cartons, corrugated boxes are manufactured using a unique layered structure that includes an inner fluted medium sandwiched between two flat linerboards. This design gives corrugated material its superior cushioning performance and crush resistance, which is why it is used in more than 90% of all shipping packaging worldwide.

The key difference lies in the material composition: the fluting (wavy layer) serves as a shock absorber during handling, while the linerboards provide rigidity and surface strength. Together, they form a lightweight but incredibly durable box that protects a wide range of products—from fragile glassware to electronics and heavy industrial parts.

Corrugated boxes come in various wall thicknesses and structural combinations, which allows for full customization depending on your product’s size, weight, and shipping environment. Whether you’re a retail brand looking for printed e-commerce boxes or a manufacturer in need of export-grade heavy-duty cartons, corrugated packaging offers a scalable solution tailored to your supply chain needs.

At POZI Packaging, we design and manufacture corrugated boxes that meet your product’s specific shipping, branding, and sustainability requirements—providing protection without compromise.

Cardboard vs Corrugated – What’s the Difference?

While often used interchangeably, cardboard and corrugated are two distinctly different materials—understanding the difference is critical when selecting the right packaging for your product.

In the world of packaging, confusion between “cardboard” and “corrugated” is extremely common. Many assume both terms refer to the same material, but their performance characteristics, construction, and ideal use cases are completely different.

What Is Cardboard?

Cardboard, in its simplest form, refers to thick paperboard or heavy-duty paper stock. It is typically used in folding cartons for lightweight items such as cereal boxes, gift sleeves, or tissue cartons. While it is cost-effective and easy to print on, cardboard lacks the structural strength needed for shipping or protective applications. It offers minimal resistance to crushing, tearing, or impact.

What Is Corrugated Material?

Corrugated board, on the other hand, consists of three or more layers: a central fluted medium and two outer linerboards. This construction dramatically improves the board’s strength-to-weight ratio, making it suitable for transporting heavy, fragile, or high-value goods.

Corrugated packaging provides:

- Enhanced compression resistance

- Superior shock absorption

- Stackability without collapsing

- Increased customization with multiple wall and flute options

Key Differences at a Glance

| Feature | Cardboard | Corrugated Board |

|---|---|---|

| Structure | Single layer of paperboard | Three-layer minimum (liner + flute + liner) |

| Protective strength | Low | High (impact, crush, stacking) |

| Best used for | Retail display, inserts | Shipping boxes, storage cartons |

| Reusability | Limited | High, especially in multi-wall formats |

| Common examples | Cereal boxes, cosmetic sleeves | Mailer boxes, e-commerce packaging |

So, if you’re looking for shipping-grade protection, corrugated is your go-to solution. Cardboard may still play a supporting role—for instance, as internal dividers or sleeves within a corrugated structure—but it should not be relied on for structural packaging alone.

At POZI, we help clients identify the appropriate material for each application—balancing cost, sustainability, and performance.

Understanding Liner Materials in Corrugated Packaging

The choice of liner material directly influences the strength, appearance, and sustainability of your corrugated box—making it one of the most important considerations in structural packaging design.

A corrugated board is composed of multiple layers, and among these, the linerboard serves as the outer and inner surfaces of the box. These layers not only contribute to the overall durability of the box, but also determine how well your packaging resists moisture, handles weight, and supports high-quality printing.

There are three commonly used liner materials in corrugated production:

1. Kraft Liner (Virgin Fiber-Based)

Kraft paper liners are the gold standard in durability and sustainability.

Made primarily from 70–80% virgin chemical pulp, Kraft liners offer superior strength and stiffness. Their high fiber purity provides excellent resistance to puncture, moisture, and crushing forces—making them ideal for heavy-duty applications such as export packaging, industrial transport, and e-commerce boxes that require double stacking.

Kraft liners also have:

- A smooth surface that accepts flexographic and offset printing

- Better tear resistance

- Greater consistency in humid or rough shipping environments

However, due to the use of virgin fibers, Kraft paper is the most expensive of the liner options. Businesses focused on premium quality and long-distance logistics often choose this material despite the higher cost.

2. Test Liner (Recycled Fiber-Based)

Test liners are a more economical and environmentally friendly alternative to Kraft liners.

Composed mostly of recycled fibers, test liners are widely used as the inner layer of corrugated boards. While not as strong or tear-resistant as Kraft, they still offer acceptable durability for general-use boxes, especially those used in short-haul deliveries or dry storage conditions.

Key traits of test liners:

- Lower cost per unit

- Lower stiffness and water resistance

- Slightly rougher surface texture, which may reduce print clarity

- Ideal for secondary packaging or protective inner cartons

Test liners are popular in cost-sensitive applications, where outer print performance and structural compression are not the highest priorities.

3. Fluting (Corrugated Medium)

The fluting layer is the core of the corrugated board, responsible for the shock-absorbing and stacking strength of the box.

Fluting papers are typically made from:

- Semi-chemical pulp (Semi-Chem) – Offers better strength, moisture resistance, and stability

- 100% Recycled pulp (Waste-Based) – More economical but slightly weaker under humid or high-pressure conditions

The fluting is glued between the linerboards and provides cushioning, rigidity, and vertical compression resistance. The quality and origin of the fluting paper directly affect the crush resistance and longevity of your packaging.

How to Choose the Right Liner Combination

Your linerboard selection depends on a mix of performance goals, budget, printing requirements, and environmental priorities:

| Use Case | Recommended Liner Setup |

|---|---|

| Export or long-distance shipping | Kraft outer + Semi-Chem fluting + Test inner |

| Domestic lightweight e-commerce | Test outer + Waste-Based fluting + Test inner |

| Luxury or retail printed boxes | White-top Kraft liner + E-flute for fine print |

| Sustainable packaging initiatives | 100% recycled test liner + waste-based fluting |

At POZI, we tailor every corrugated solution with the most suitable liner-flute combination to meet your packaging objectives, logistics environment, and brand presentation—without compromising cost-efficiency or sustainability targets.

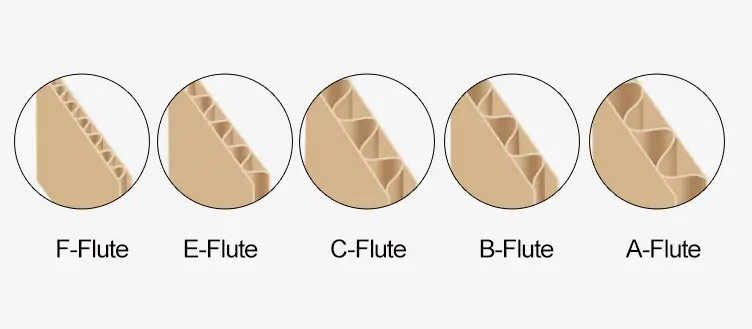

Corrugated Flute Types: Choosing the Right Grade for Performance and Print

Flute grade selection is a critical part of custom corrugated packaging—it determines your box’s strength, cushioning, stackability, and print surface quality.

A corrugated box’s middle layer—the fluting—acts as the backbone of its protective performance. Flute grades refer to the thickness and shape of the wave-like structure that sits between the linerboards. Each grade delivers different physical properties and is suited for specific packaging functions.

Understanding the characteristics of each flute type allows you to design packaging that matches your product’s fragility, weight, storage conditions, and visual expectations.

A-Flute: Maximum Cushioning & Compression Resistance (Approx. 1/4″)

A-Flute offers the thickest and most cushioned structure among all flute grades.

With approximately 33–38 flutes per linear foot, A-Flute provides excellent vertical strength and shock absorption. It is ideal for:

- Fragile or oversized items (glassware, electronics)

- Products requiring thermal insulation

- Packaging that will be heavily stacked during shipping

However, due to its thickness, it may not be the best option where high-quality printing or compact box sizes are a priority.

B-Flute: Compact Strength with a Smooth Print Surface (Approx. 1/8″)

B-Flute balances strength and printability—ideal for retail and die-cut applications.

With 47–53 flutes per linear foot, B-Flute provides excellent resistance to puncturing, crushing, and folding. It also features a relatively smooth surface, making it well-suited for:

- POP displays

- Die-cut mailers

- Custom printed boxes

- Inner dividers or pads

It is one of the most commonly used flute types for e-commerce boxes and branded consumer packaging, due to its print-friendliness and manageable thickness.

C-Flute: Versatile & Widely Used (Approx. 3/16″)

C-Flute is the workhorse of the corrugated industry, offering a balanced mix of stacking strength and cushioning.

With 39–43 flutes per foot, C-Flute provides enough rigidity for shipping cartons, while still offering decent print performance. It is often used for:

- Food and beverage boxes (milk, juice, canned goods)

- Furniture or appliance packaging

- General-purpose shipping boxes

C-Flute is also widely combined with others (e.g., in AC or BC double wall combinations) to improve shock resistance and load-bearing capacity.

E-Flute: Thin, Sharp, and Designed for Fine Print (Approx. 1/16″)

E-Flute offers the ideal surface for high-resolution graphics, making it perfect for printed retail boxes and luxury branding.

With 94–96 flutes per foot, it has the highest flute density, which:

- Provides excellent crush resistance

- Supports sharp, vivid printing

- Minimizes surface warping

Common use cases include:

- Cosmetics

- Small electronics

- Fragile retail items in shelf-ready packaging

Its slim profile also makes it popular for folding carton replacements where extra strength is needed without adding bulk.

F-Flute: Ultra-Thin and Premium-Print Ready (Approx. 1/32″)

F-Flute is even finer than E, offering a near-flat surface ideal for luxury and specialty packaging.

With over 120 flutes per foot, F-Flute provides:

- Smoothest possible surface for offset or digital printing

- A refined unboxing experience

- Light but rigid structural support

Applications include:

- Premium confectionery packaging

- Rigid presentation kits

- Retail boxes with high-gloss or foil finishes

In markets like Europe, F-Flute is increasingly favored for retail shelf impact and eco-conscious luxury brands.

Flute Grade Selection at a Glance

| Flute Type | Thickness (approx.) | Best For | Printability |

|---|---|---|---|

| A-Flute | 1/4″ (6.5 mm) | Fragile items, heavy stacking | Low |

| B-Flute | 1/8″ (3.2 mm) | Branded boxes, die-cut, retail | Good |

| C-Flute | 3/16″ (4.8 mm) | General shipping, food packaging | Moderate |

| E-Flute | 1/16″ (1.6 mm) | Printed retail boxes, small goods | Excellent |

| F-Flute | 1/32″ (0.8 mm) | High-end printed packaging, gift boxes | Outstanding |

At POZI Packaging, we help you select the right flute grade—or combination of grades—to deliver the optimal balance of performance, appearance, and cost-efficiency. Whether you’re building e-commerce mailers or rigid luxury kits, we structure your box from the inside out for impact, protection, and brand value.

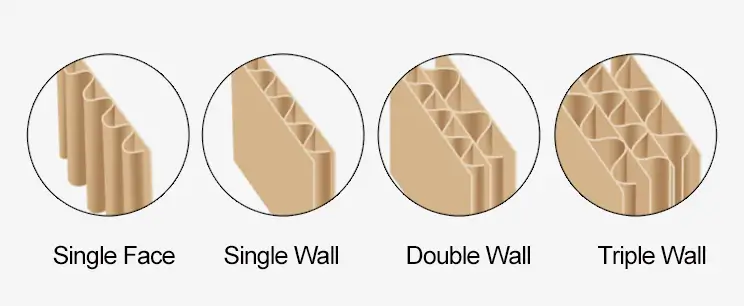

Types of Corrugated Board Structures: From Lightweight to Heavy-Duty Applications

Corrugated board is not a one-size-fits-all material—by adjusting the number and type of layers, you can create packaging solutions that range from minimal padding to industrial-grade protection.

Corrugated packaging isn’t just about the flute grade—it’s also about how many layers of liners and fluted mediums are combined in the final board. These structural variations allow packaging engineers to fine-tune strength, rigidity, flexibility, and cost for specific product types and transport requirements.

Let’s explore the most common types of corrugated board constructions:

1. Single Face Board – Flexible and Cost-Effective for Inner Protection

Single Face corrugated board consists of one flat linerboard bonded to a fluted medium, with the second side left open and exposed.

- Structure: 1 liner + 1 flute

- Use cases: Wrapping delicate items, protective inner padding, roll stock packaging

- Advantages: Flexible, easy to bend or roll, lower cost and material usage

- Limitations: Not suitable for standalone shipping—requires outer support

Single face is ideal for interleaving layers between products, or as shock-absorbing inner wrap within a larger shipping box.

2. Single Wall Board – The Industry Standard for Most Corrugated Boxes

Single Wall board, also known as double-faced corrugated, is the most widely used format for packaging boxes.

- Structure: Liner + Flute + Liner

- Use cases: Shipping boxes, e-commerce cartons, mailer boxes, retail packaging

- Advantages: Balanced strength, cost-efficiency, and printability

- Flute options: A, B, C, E, or F depending on the application

This construction supports a wide variety of box styles (such as RSC, mailers, tuck-top boxes) and offers sufficient rigidity for most light-to-medium-weight products.

3. Double Wall Board – Reinforced Structure for Heavier Loads

Double Wall board combines two layers of fluting and three linerboards, offering significantly increased strength and resistance to crushing or puncture.

- Structure: Liner + Flute + Liner + Flute + Liner

- Use cases: Industrial equipment, automotive parts, stacked pallet shipments

- Advantages: Higher stacking strength, better resistance to deformation under weight, impact resistance

- Common combinations: BC Flute (B + C), EB Flute (E + B), AC Flute (A + C)

The pairing of coarse and fine flutes allows customization of both internal protection and external print quality.

4. Triple Wall Board – Maximum Protection for Extreme Shipping Demands

Triple Wall board is the most heavy-duty corrugated format, with three fluted mediums and four linerboards.

- Structure: Liner + Flute + Liner + Flute + Liner + Flute + Liner

- Use cases: Bulk shipments, chemicals, heavy machinery, export packaging

- Load capacity: Can support up to 300 lbs or more

- Advantages: Exceptional crush resistance, water resistance (with coating), and long-term structural integrity

While less flexible and more costly, triple wall is unmatched in protection, load-bearing capacity, and suitability for international freight or high-risk environments.

Flute Combinations in Multi-Wall Boards

By combining different flute grades within the same board structure, manufacturers can fine-tune performance across multiple variables—such as vertical compression, cushioning, and print quality. Common examples include:

| Flute Combo | Features |

|---|---|

| BC Flute | Most common double wall; strong stacking + good puncture resistance |

| EB Flute | Enhanced printing surface (E) + solid internal cushioning (B) |

| AC Flute | Maximum strength for bulk or export packaging; great for high-impact loads |

At POZI, we analyze your shipping conditions, storage environment, and branding needs to recommend the optimal board type and flute configuration—ensuring your packaging performs as well as your product.

Corrugated Box Styles: Structural Options Tailored to Your Packaging Needs

Corrugated boxes come in a variety of structural styles—each engineered to meet different functional, aesthetic, and logistical requirements. Choosing the right style means balancing protection, usability, and brand presentation.

While the material and flute type define the core strength of your packaging, the box style determines how the packaging functions in real-world use: how it’s assembled, how it opens, how it supports the product, and how it contributes to unboxing experience.

Let’s explore the most commonly used corrugated box structures and their ideal applications:

1. Regular Slotted Container (RSC)

The RSC is the most standard and cost-efficient box style in global packaging.

- Structure: All flaps are the same length; outer flaps meet in the center when closed

- Assembly: Shipped flat; requires taping or gluing at the bottom and top

- Best for: General shipping, warehousing, wholesale packaging

- Advantages: Minimal waste, high stacking strength, efficient palletization

This is the go-to option for bulk shipping, especially in logistics-heavy industries like manufacturing, food, and retail distribution.

2. Full Overlap Slotted Container (FOL)

An FOL box has outer flaps that completely overlap, offering extra strength and protection.

- Benefits: Double thickness on top and bottom improves impact resistance

- Applications: Heavy or fragile products, multi-item kits, sensitive machinery

This style is preferred for products that require enhanced protection on box edges—especially when stacking or transporting across long distances.

3. Half Slotted Container (HSC)

The HSC has flaps only on the bottom—leaving the top open or covered by a separate lid.

- Best used for: Shelf-stored items, archival packaging, warehouse pick bins

- Advantages: Quick access, easy display, ideal for inner carton configurations

Often used in combination with die-cut lids, the HSC box is excellent for storage solutions or semi-permanent retail setups.

4. Roll End Tuck Front (RETF)

The RETF style is widely used in e-commerce and luxury retail for its clean, secure closure.

- Structure: Folded sides and tuck-in front panel without need for tape

- Advantages: Excellent presentation, secure yet tool-free opening

- Ideal for: Subscription boxes, printed mailers, electronics, premium product kits

This design is often paired with E- or F-flute for enhanced printing quality and a refined consumer experience.

5. One-Piece Folder (OPF)

A wrap-style box designed for flat items such as books, framed prints, or clothing.

- Structure: Single sheet scored and folded around the product

- Benefits: Low material waste, flat shipping, easy manual assembly

- Use cases: Online apparel brands, book publishers, printed collateral

Due to its versatility and low profile, OPF boxes are a go-to for thin or soft products shipped directly to consumers.

6. Tuck Top Auto Bottom

Combining fast assembly with secure closure, this style speeds up packing workflows.

- Features: Pre-glued auto-lock bottom + tuck-in top flaps

- Applications: Mid-volume retail, cosmetics, FMCG brands

- Advantages: Time-saving for fulfillment, customizable for branding

Common in automated packing lines and high-throughput order systems, this style offers both form and function.

7. Tab Lock Roll End & 3-Flap Tuck Boxes

Ideal for secure closure without glue or tape, especially in direct-to-consumer packaging.

- Tab Lock Boxes use side locks to hold structure without adhesives

- 3-Flap Tuck Boxes offer extra closure layers for increased stability

These are often used in gifting, promotional packaging, or high-end retail, where both function and aesthetics matter.

Box Style Selection Guide

| Box Style | Best For | Key Benefit |

|---|---|---|

| RSC | Bulk shipping, general goods | Most cost-efficient, stackable |

| FOL | Fragile, heavy products | Reinforced bottom/top, strong edges |

| RETF | Branded e-commerce boxes | Presentation-focused, tape-free |

| HSC | Storage and pick bins | Open top, versatile with lids |

| OPF | Books, garments, printed media | Low-profile, wraparound style |

| Tuck Top Auto Bottom | Cosmetics, retail kits | Quick assembly, ideal for automation |

| Tab Lock / 3-Flap Tuck | Gifting, premium retail boxes | Secure without tape, elegant user experience |

At POZI Packaging, we help clients evaluate not just box strength, but also packing workflow, product handling, branding needs, and cost per unit—delivering box styles that match your operational and marketing goals.

Quality Control Tests for Corrugated Packaging: Ensuring Performance from Production to Delivery

Corrugated packaging is only as reliable as the tests it passes—quality control ensures your boxes perform under pressure, literally.

Corrugated boxes undergo significant physical stress throughout their lifecycle—from factory handling and logistics stacking to international shipping and end-customer delivery. Without proper testing, even a well-designed box may fail when exposed to compression, shock, or puncture in real-world conditions.

To prevent product loss, damaged shipments, or rejected export batches, packaging manufacturers apply a series of standardized quality control tests that verify the strength, durability, and reliability of the corrugated material.

Here are the three most commonly used testing methods:

1. Edge Crush Test (ECT): Measuring Stack Strength

The ECT measures how much vertical pressure a corrugated board edge can withstand before collapsing.

- Purpose: Determines the load-bearing capacity of the box in stacked conditions

- Process: A vertical force is applied perpendicular to the edge of a sample board until it buckles

- Result: Reported in pounds per inch (e.g., 32 ECT), indicating stacking strength

ECT is particularly relevant for warehouse storage, palletization, and logistics optimization, where boxes are often stacked high. An underestimated ECT rating can result in bottom-layer failure and costly damages.

Common Use Cases:

- 32 ECT: Standard single-wall box for lightweight shipments

- 44–48 ECT: Double-wall boxes for heavier or export items

2. Flat Crush Test (FCT): Measuring Flute Resilience

The FCT evaluates how much pressure the corrugated fluting can handle before it is flattened.

- Purpose: Assesses flute structure’s ability to maintain cushioning under surface compression

- Process: A flat pressure is applied directly onto the board’s surface until the flutes collapse

- Relevance: Indicates the box’s ability to absorb shocks and resist deformation during transit

This test is important for fragile products, where the internal cushioning effect of the flutes is crucial to prevent breakage.

3. Mullen Test (Burst Test): Testing Puncture Resistance

The Mullen Test measures the force required to rupture the corrugated board using hydraulic pressure.

- Purpose: Evaluates overall tensile strength and durability under rough handling

- Measurement Unit: Pounds per square inch (psi) required to burst the board

- Typical Ratings: Ranges from 150 to 300 psi depending on the board composition

Mullen-rated boxes are often required for export markets, military use, or hazardous materials, where packaging regulations demand higher puncture and burst strength.

Why These Tests Matter in Real-World Applications

| Test | What It Protects Against | Use Case |

|---|---|---|

| Edge Crush Test | Collapse from stacking | E-commerce, warehouses, supply chain stacking |

| Flat Crush Test | Flute damage under pressure | Glassware, cosmetics, consumer electronics |

| Mullen Test | Tears, punctures, shipping abuse | Export packaging, B2B logistics, regulatory compliance |

At POZI Packaging, we rigorously test every corrugated structure through internal QC protocols and provide certified documentation when needed—especially for clients involved in international shipping, regulated industries, or fragile product categories.

These tests are not optional—they are essential for ensuring your packaging not only meets but exceeds performance expectations in transit and in storage.

Benefits of Corrugated Packaging: Why It Remains the Industry’s Top Choice

Corrugated packaging offers the ideal balance of strength, sustainability, and customization—making it the most trusted solution for manufacturers, retailers, and global logistics providers alike.

Across industries, corrugated boxes have become the default packaging solution for one key reason: they work. Their unique combination of multi-layered structure, material versatility, and scalable design makes them suitable for everything from fragile e-commerce shipments to heavy-duty export containers.

Let’s explore the key benefits in detail:

1. Exceptional Product Protection

Corrugated boxes are engineered to absorb shock, resist crushing, and maintain structural integrity throughout the supply chain.

The layered construction—fluted medium between flat liners—creates air pockets that cushion products from mechanical impact. This makes corrugated packaging ideal for:

- Fragile items (glass, ceramics, electronics)

- Items exposed to vibrations or drops in transit

- Stackable pallet shipments in warehouses

The board grade and flute type can be precisely matched to your product’s weight and fragility, ensuring that your goods arrive safe, intact, and professionally presented.

2. Highly Customizable for Product and Brand

Corrugated packaging can be engineered and printed to reflect both structural and visual needs.

From internal inserts and folding mechanisms to multi-color printing and premium surface finishes, corrugated boxes offer extensive flexibility:

- Custom die-cuts for form-fitting compartments

- Offset and flexo printing for high-impact branding

- Lamination, embossing, spot UV, and foil options for retail appeal

Whether you’re shipping industrial tools or luxury candles, corrugated boxes can be adapted to enhance functionality and customer experience.

3. Lightweight and Cost-Efficient

Corrugated packaging delivers protective strength without adding significant weight—helping reduce shipping and handling costs.

Compared to wood, plastic, or metal containers, corrugated boxes:

- Weigh less, lowering freight charges

- Can be flat-packed, reducing storage and warehouse space

- Require less energy to manufacture and recycle

This makes them ideal for cost-sensitive markets, especially where packaging is single-use or subject to frequent design updates.

4. Environmentally Friendly and Recyclable

Corrugated cardboard is one of the most sustainable materials in commercial packaging.

Most corrugated boxes today are made from 70–100% recycled fibers, and are:

- Biodegradable in natural conditions

- Recyclable through standard municipal systems

- Renewable, as kraft paper is typically sourced from managed forests

Additionally, corrugated board can be re-engineered for minimal material waste through smart dieline layouts and right-sizing strategies—helping your brand reduce its carbon footprint without compromising product protection.

At POZI Packaging, we offer FSC-certified corrugated solutions and help clients transition to plastic-free packaging alternatives aligned with ESG goals.

5. Scalable for Every Industry

Corrugated packaging can serve industries ranging from:

- E-commerce: Custom mailers, printed shipping boxes, subscription kits

- Retail & Luxury: Offset-printed rigid-style corrugated boxes with premium finishes

- Food & Beverage: Stackable cartons with moisture barriers or greaseproof coatings

- Industrial: Heavy-duty double/triple wall corrugated for large or hazardous goods

- Logistics: Pallet-ready configurations with clear BMC labeling for export

Its universal applicability means you don’t need to reinvent your packaging system as your business grows—corrugated scales with you.

Are There Any Drawbacks to Corrugated Packaging? Understanding the Limitations and How to Address Them

While corrugated packaging offers unmatched versatility and protective value, it’s important to understand its limitations—so you can design smarter, more cost-effective solutions.

No packaging material is perfect in every scenario. Corrugated cardboard, despite being a top-tier option in most industries, comes with certain drawbacks that must be acknowledged and planned for, especially in applications involving extreme environments, long-term storage, or ultra-low-margin product lines.

Let’s break down the most common challenges and how you can manage them effectively:

1. Susceptibility to Moisture and Weather Conditions

Corrugated board is inherently absorbent, making it vulnerable to water damage if not properly treated.

Uncoated corrugated boxes may lose rigidity, warp, or delaminate when exposed to:

- Humid storage conditions

- Rain during transit

- Cold-chain or frozen supply chains

Mitigation Strategies:

- Apply moisture-resistant coatings or lamination films

- Use PE-lined or waxed liners for refrigerated packaging

- Select plastic corrugated or hybrid materials for specific cold-chain use

At POZI, we offer water-resistant coatings and custom structural solutions for clients in the food, pharma, and agricultural sectors.

2. Higher Cost Compared to Low-End Packaging Alternatives

Corrugated packaging—especially when customized—can be more expensive than simple paperboard cartons or plastic bags.

Costs are influenced by:

- Paper raw material market fluctuations

- Added structural layers (double/triple wall)

- Custom die-cutting, printing, or coatings

- Freight costs due to larger unfolded size (for bulky boxes)

Mitigation Strategies:

- Use single-wall construction with smart inserts instead of double-wall

- Optimize box dimensions with right-sizing to reduce material usage

- Consolidate designs across SKUs to achieve economies of scale

- Choose standardized box styles with minor print variation to cut tooling costs

Our team at POZI helps you analyze cost-per-unit vs. protection level, so you can optimize packaging economics without compromising product safety or brand value.

3. Limited Longevity in Harsh Environments

Corrugated boxes are designed primarily for short- to medium-term protection—not for indefinite storage or exposure to high mechanical stress.

In long-term warehousing or rugged industrial handling, cardboard may:

- Soften over time

- Attract insects in improper storage

- Lose compression strength under prolonged vertical load

Mitigation Strategies:

- Rotate stock regularly

- Store in controlled environments

- Reinforce boxes with additional interior structures or edge protectors

If you’re looking for packaging that will be reused multiple times (e.g., returnable containers), corrugated may not be the most durable choice—but it remains optimal for one-way transit and display-ready logistics.

Balancing the Downsides with Strategic Packaging Design

Corrugated packaging isn’t flawless—but when used strategically, its limitations can be effectively managed through:

- Material optimization

- Protective coatings

- Functional inserts

- Right-size engineering

- Box-style selection based on use case

At POZI, we don’t just manufacture boxes—we help you think through real-world usage, shipping risks, and lifecycle costs, ensuring your packaging performs consistently across all environments.

Ready to Build Your Custom Corrugated Boxes? Let’s Get Started.

Choosing the right corrugated packaging isn’t just about material—it’s about aligning structure, protection, branding, and logistics into one cohesive solution that supports your business goals.

Whether you’re shipping electronics across borders, delivering subscription kits to consumers, or launching a new retail line, your packaging is more than just a box—it’s your first impression, your protective barrier, and your silent brand ambassador.

At POZI Packaging, we combine engineering precision with market insight to help you design corrugated packaging that fits your product, your process, and your identity.

Here’s what we offer:

- 🧩 Tailored Structural Engineering

We analyze your product’s weight, fragility, and shipment method to recommend the ideal flute type, wall structure, and box style. - 🎨 Custom Print & Branding Options

From single-color logos to full-surface offset printing with premium finishes—we help your box stand out on the shelf or doorstep. - 📦 Low Minimums & Scalable Production

Whether you’re a startup or an established brand, we offer flexibility with MOQ-friendly batch runs and full-scale production capacity. - 🌍 Sustainable Materials, Certified Solutions

FSC-certified, recyclable, and customizable to meet your ESG goals without compromising performance. - 🧪 Performance Testing & Export-Ready Packaging

All boxes are tested for ECT, burst strength, and stacking performance—complete with Box Maker’s Certificates (BMC) for customs and compliance.

Let’s Create Smarter, Stronger Packaging—Together

Tell us what you need: the product, the use case, the destination—and we’ll take care of the rest.

📩 Reach out today to speak with a packaging engineer, request dieline support, or get a free structural consultation and quote.

With POZI, your packaging does more than protect—it performs, presents, and propels your brand forward.

What Is a Corrugated Box?

Corrugated boxes are engineered packaging solutions built for strength, durability, and product protection—making them the backbone of global logistics and e-commerce shipping.

Unlike simple cardboard cartons, corrugated boxes are manufactured using a unique layered structure that includes an inner fluted medium sandwiched between two flat linerboards. This design gives corrugated material its superior cushioning performance and crush resistance, which is why it is used in more than 90% of all shipping packaging worldwide.

The key difference lies in the material composition: the fluting (wavy layer) serves as a shock absorber during handling, while the linerboards provide rigidity and surface strength. Together, they form a lightweight but incredibly durable box that protects a wide range of products—from fragile glassware to electronics and heavy industrial parts.

Corrugated boxes come in various wall thicknesses and structural combinations, which allows for full customization depending on your product’s size, weight, and shipping environment. Whether you’re a retail brand looking for printed e-commerce boxes or a manufacturer in need of export-grade heavy-duty cartons, corrugated packaging offers a scalable solution tailored to your supply chain needs.

At POZI Packaging, we design and manufacture corrugated boxes that meet your product’s specific shipping, branding, and sustainability requirements—providing protection without compromise.

Cardboard vs Corrugated – What’s the Difference?

While often used interchangeably, cardboard and corrugated are two distinctly different materials—understanding the difference is critical when selecting the right packaging for your product.

In the world of packaging, confusion between “cardboard” and “corrugated” is extremely common. Many assume both terms refer to the same material, but their performance characteristics, construction, and ideal use cases are completely different.

What Is Cardboard?

Cardboard, in its simplest form, refers to thick paperboard or heavy-duty paper stock. It is typically used in folding cartons for lightweight items such as cereal boxes, gift sleeves, or tissue cartons. While it is cost-effective and easy to print on, cardboard lacks the structural strength needed for shipping or protective applications. It offers minimal resistance to crushing, tearing, or impact.

What Is Corrugated Material?

Corrugated board, on the other hand, consists of three or more layers: a central fluted medium and two outer linerboards. This construction dramatically improves the board’s strength-to-weight ratio, making it suitable for transporting heavy, fragile, or high-value goods.

Corrugated packaging provides:

- Enhanced compression resistance

- Superior shock absorption

- Stackability without collapsing

- Increased customization with multiple wall and flute options

Key Differences at a Glance

| Feature | Cardboard | Corrugated Board |

|---|---|---|

| Structure | Single layer of paperboard | Three-layer minimum (liner + flute + liner) |

| Protective strength | Low | High (impact, crush, stacking) |

| Best used for | Retail display, inserts | Shipping boxes, storage cartons |

| Reusability | Limited | High, especially in multi-wall formats |

| Common examples | Cereal boxes, cosmetic sleeves | Mailer boxes, e-commerce packaging |

So, if you’re looking for shipping-grade protection, corrugated is your go-to solution. Cardboard may still play a supporting role—for instance, as internal dividers or sleeves within a corrugated structure—but it should not be relied on for structural packaging alone.

At POZI, we help clients identify the appropriate material for each application—balancing cost, sustainability, and performance.

Understanding Liner Materials in Corrugated Packaging

The choice of liner material directly influences the strength, appearance, and sustainability of your corrugated box—making it one of the most important considerations in structural packaging design.

A corrugated board is composed of multiple layers, and among these, the linerboard serves as the outer and inner surfaces of the box. These layers not only contribute to the overall durability of the box, but also determine how well your packaging resists moisture, handles weight, and supports high-quality printing.

There are three commonly used liner materials in corrugated production:

1. Kraft Liner (Virgin Fiber-Based)

Kraft paper liners are the gold standard in durability and sustainability.

Made primarily from 70–80% virgin chemical pulp, Kraft liners offer superior strength and stiffness. Their high fiber purity provides excellent resistance to puncture, moisture, and crushing forces—making them ideal for heavy-duty applications such as export packaging, industrial transport, and e-commerce boxes that require double stacking.

Kraft liners also have:

- A smooth surface that accepts flexographic and offset printing

- Better tear resistance

- Greater consistency in humid or rough shipping environments

However, due to the use of virgin fibers, Kraft paper is the most expensive of the liner options. Businesses focused on premium quality and long-distance logistics often choose this material despite the higher cost.

2. Test Liner (Recycled Fiber-Based)

Test liners are a more economical and environmentally friendly alternative to Kraft liners.

Composed mostly of recycled fibers, test liners are widely used as the inner layer of corrugated boards. While not as strong or tear-resistant as Kraft, they still offer acceptable durability for general-use boxes, especially those used in short-haul deliveries or dry storage conditions.

Key traits of test liners:

- Lower cost per unit

- Lower stiffness and water resistance

- Slightly rougher surface texture, which may reduce print clarity

- Ideal for secondary packaging or protective inner cartons

Test liners are popular in cost-sensitive applications, where outer print performance and structural compression are not the highest priorities.

3. Fluting (Corrugated Medium)

The fluting layer is the core of the corrugated board, responsible for the shock-absorbing and stacking strength of the box.

Fluting papers are typically made from:

- Semi-chemical pulp (Semi-Chem) – Offers better strength, moisture resistance, and stability

- 100% Recycled pulp (Waste-Based) – More economical but slightly weaker under humid or high-pressure conditions

The fluting is glued between the linerboards and provides cushioning, rigidity, and vertical compression resistance. The quality and origin of the fluting paper directly affect the crush resistance and longevity of your packaging.

How to Choose the Right Liner Combination

Your linerboard selection depends on a mix of performance goals, budget, printing requirements, and environmental priorities:

| Use Case | Recommended Liner Setup |

|---|---|

| Export or long-distance shipping | Kraft outer + Semi-Chem fluting + Test inner |

| Domestic lightweight e-commerce | Test outer + Waste-Based fluting + Test inner |

| Luxury or retail printed boxes | White-top Kraft liner + E-flute for fine print |

| Sustainable packaging initiatives | 100% recycled test liner + waste-based fluting |

At POZI, we tailor every corrugated solution with the most suitable liner-flute combination to meet your packaging objectives, logistics environment, and brand presentation—without compromising cost-efficiency or sustainability targets.

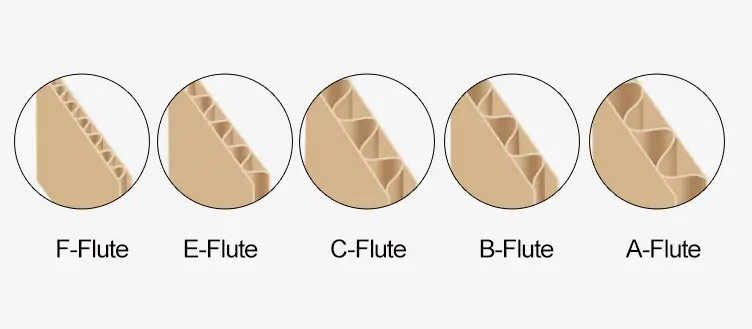

Corrugated Flute Types: Choosing the Right Grade for Performance and Print

Flute grade selection is a critical part of custom corrugated packaging—it determines your box’s strength, cushioning, stackability, and print surface quality.

A corrugated box’s middle layer—the fluting—acts as the backbone of its protective performance. Flute grades refer to the thickness and shape of the wave-like structure that sits between the linerboards. Each grade delivers different physical properties and is suited for specific packaging functions.

Understanding the characteristics of each flute type allows you to design packaging that matches your product’s fragility, weight, storage conditions, and visual expectations.

A-Flute: Maximum Cushioning & Compression Resistance (Approx. 1/4″)

A-Flute offers the thickest and most cushioned structure among all flute grades.

With approximately 33–38 flutes per linear foot, A-Flute provides excellent vertical strength and shock absorption. It is ideal for:

- Fragile or oversized items (glassware, electronics)

- Products requiring thermal insulation

- Packaging that will be heavily stacked during shipping

However, due to its thickness, it may not be the best option where high-quality printing or compact box sizes are a priority.

B-Flute: Compact Strength with a Smooth Print Surface (Approx. 1/8″)

B-Flute balances strength and printability—ideal for retail and die-cut applications.

With 47–53 flutes per linear foot, B-Flute provides excellent resistance to puncturing, crushing, and folding. It also features a relatively smooth surface, making it well-suited for:

- POP displays

- Die-cut mailers

- Custom printed boxes

- Inner dividers or pads

It is one of the most commonly used flute types for e-commerce boxes and branded consumer packaging, due to its print-friendliness and manageable thickness.

C-Flute: Versatile & Widely Used (Approx. 3/16″)

C-Flute is the workhorse of the corrugated industry, offering a balanced mix of stacking strength and cushioning.

With 39–43 flutes per foot, C-Flute provides enough rigidity for shipping cartons, while still offering decent print performance. It is often used for:

- Food and beverage boxes (milk, juice, canned goods)

- Furniture or appliance packaging

- General-purpose shipping boxes

C-Flute is also widely combined with others (e.g., in AC or BC double wall combinations) to improve shock resistance and load-bearing capacity.

E-Flute: Thin, Sharp, and Designed for Fine Print (Approx. 1/16″)

E-Flute offers the ideal surface for high-resolution graphics, making it perfect for printed retail boxes and luxury branding.

With 94–96 flutes per foot, it has the highest flute density, which:

- Provides excellent crush resistance

- Supports sharp, vivid printing

- Minimizes surface warping

Common use cases include:

- Cosmetics

- Small electronics

- Fragile retail items in shelf-ready packaging

Its slim profile also makes it popular for folding carton replacements where extra strength is needed without adding bulk.

F-Flute: Ultra-Thin and Premium-Print Ready (Approx. 1/32″)

F-Flute is even finer than E, offering a near-flat surface ideal for luxury and specialty packaging.

With over 120 flutes per foot, F-Flute provides:

- Smoothest possible surface for offset or digital printing

- A refined unboxing experience

- Light but rigid structural support

Applications include:

- Premium confectionery packaging

- Rigid presentation kits

- Retail boxes with high-gloss or foil finishes

In markets like Europe, F-Flute is increasingly favored for retail shelf impact and eco-conscious luxury brands.

Flute Grade Selection at a Glance

| Flute Type | Thickness (approx.) | Best For | Printability |

|---|---|---|---|

| A-Flute | 1/4″ (6.5 mm) | Fragile items, heavy stacking | Low |

| B-Flute | 1/8″ (3.2 mm) | Branded boxes, die-cut, retail | Good |

| C-Flute | 3/16″ (4.8 mm) | General shipping, food packaging | Moderate |

| E-Flute | 1/16″ (1.6 mm) | Printed retail boxes, small goods | Excellent |

| F-Flute | 1/32″ (0.8 mm) | High-end printed packaging, gift boxes | Outstanding |

At POZI Packaging, we help you select the right flute grade—or combination of grades—to deliver the optimal balance of performance, appearance, and cost-efficiency. Whether you’re building e-commerce mailers or rigid luxury kits, we structure your box from the inside out for impact, protection, and brand value.

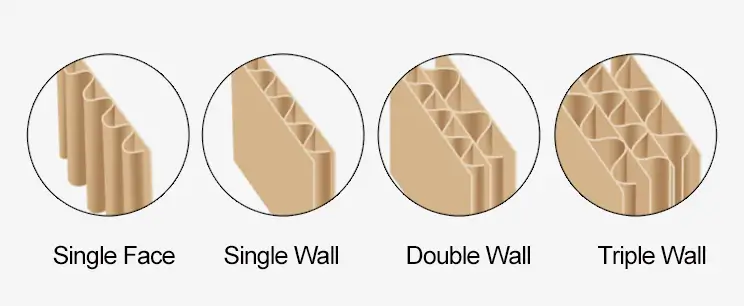

Types of Corrugated Board Structures: From Lightweight to Heavy-Duty Applications

Corrugated board is not a one-size-fits-all material—by adjusting the number and type of layers, you can create packaging solutions that range from minimal padding to industrial-grade protection.

Corrugated packaging isn’t just about the flute grade—it’s also about how many layers of liners and fluted mediums are combined in the final board. These structural variations allow packaging engineers to fine-tune strength, rigidity, flexibility, and cost for specific product types and transport requirements.

Let’s explore the most common types of corrugated board constructions:

1. Single Face Board – Flexible and Cost-Effective for Inner Protection

Single Face corrugated board consists of one flat linerboard bonded to a fluted medium, with the second side left open and exposed.

- Structure: 1 liner + 1 flute

- Use cases: Wrapping delicate items, protective inner padding, roll stock packaging

- Advantages: Flexible, easy to bend or roll, lower cost and material usage

- Limitations: Not suitable for standalone shipping—requires outer support

Single face is ideal for interleaving layers between products, or as shock-absorbing inner wrap within a larger shipping box.

2. Single Wall Board – The Industry Standard for Most Corrugated Boxes

Single Wall board, also known as double-faced corrugated, is the most widely used format for packaging boxes.

- Structure: Liner + Flute + Liner

- Use cases: Shipping boxes, e-commerce cartons, mailer boxes, retail packaging

- Advantages: Balanced strength, cost-efficiency, and printability

- Flute options: A, B, C, E, or F depending on the application

This construction supports a wide variety of box styles (such as RSC, mailers, tuck-top boxes) and offers sufficient rigidity for most light-to-medium-weight products.

3. Double Wall Board – Reinforced Structure for Heavier Loads

Double Wall board combines two layers of fluting and three linerboards, offering significantly increased strength and resistance to crushing or puncture.

- Structure: Liner + Flute + Liner + Flute + Liner

- Use cases: Industrial equipment, automotive parts, stacked pallet shipments

- Advantages: Higher stacking strength, better resistance to deformation under weight, impact resistance

- Common combinations: BC Flute (B + C), EB Flute (E + B), AC Flute (A + C)

The pairing of coarse and fine flutes allows customization of both internal protection and external print quality.

4. Triple Wall Board – Maximum Protection for Extreme Shipping Demands

Triple Wall board is the most heavy-duty corrugated format, with three fluted mediums and four linerboards.

- Structure: Liner + Flute + Liner + Flute + Liner + Flute + Liner

- Use cases: Bulk shipments, chemicals, heavy machinery, export packaging

- Load capacity: Can support up to 300 lbs or more

- Advantages: Exceptional crush resistance, water resistance (with coating), and long-term structural integrity

While less flexible and more costly, triple wall is unmatched in protection, load-bearing capacity, and suitability for international freight or high-risk environments.

Flute Combinations in Multi-Wall Boards

By combining different flute grades within the same board structure, manufacturers can fine-tune performance across multiple variables—such as vertical compression, cushioning, and print quality. Common examples include:

| Flute Combo | Features |

|---|---|

| BC Flute | Most common double wall; strong stacking + good puncture resistance |

| EB Flute | Enhanced printing surface (E) + solid internal cushioning (B) |

| AC Flute | Maximum strength for bulk or export packaging; great for high-impact loads |

At POZI, we analyze your shipping conditions, storage environment, and branding needs to recommend the optimal board type and flute configuration—ensuring your packaging performs as well as your product.

Corrugated Box Styles: Structural Options Tailored to Your Packaging Needs

Corrugated boxes come in a variety of structural styles—each engineered to meet different functional, aesthetic, and logistical requirements. Choosing the right style means balancing protection, usability, and brand presentation.

While the material and flute type define the core strength of your packaging, the box style determines how the packaging functions in real-world use: how it’s assembled, how it opens, how it supports the product, and how it contributes to unboxing experience.

Let’s explore the most commonly used corrugated box structures and their ideal applications:

1. Regular Slotted Container (RSC)

The RSC is the most standard and cost-efficient box style in global packaging.

- Structure: All flaps are the same length; outer flaps meet in the center when closed

- Assembly: Shipped flat; requires taping or gluing at the bottom and top

- Best for: General shipping, warehousing, wholesale packaging

- Advantages: Minimal waste, high stacking strength, efficient palletization

This is the go-to option for bulk shipping, especially in logistics-heavy industries like manufacturing, food, and retail distribution.

2. Full Overlap Slotted Container (FOL)

An FOL box has outer flaps that completely overlap, offering extra strength and protection.

- Benefits: Double thickness on top and bottom improves impact resistance

- Applications: Heavy or fragile products, multi-item kits, sensitive machinery

This style is preferred for products that require enhanced protection on box edges—especially when stacking or transporting across long distances.

3. Half Slotted Container (HSC)

The HSC has flaps only on the bottom—leaving the top open or covered by a separate lid.

- Best used for: Shelf-stored items, archival packaging, warehouse pick bins

- Advantages: Quick access, easy display, ideal for inner carton configurations

Often used in combination with die-cut lids, the HSC box is excellent for storage solutions or semi-permanent retail setups.

4. Roll End Tuck Front (RETF)

The RETF style is widely used in e-commerce and luxury retail for its clean, secure closure.

- Structure: Folded sides and tuck-in front panel without need for tape

- Advantages: Excellent presentation, secure yet tool-free opening

- Ideal for: Subscription boxes, printed mailers, electronics, premium product kits

This design is often paired with E- or F-flute for enhanced printing quality and a refined consumer experience.

5. One-Piece Folder (OPF)

A wrap-style box designed for flat items such as books, framed prints, or clothing.

- Structure: Single sheet scored and folded around the product

- Benefits: Low material waste, flat shipping, easy manual assembly

- Use cases: Online apparel brands, book publishers, printed collateral

Due to its versatility and low profile, OPF boxes are a go-to for thin or soft products shipped directly to consumers.

6. Tuck Top Auto Bottom

Combining fast assembly with secure closure, this style speeds up packing workflows.

- Features: Pre-glued auto-lock bottom + tuck-in top flaps

- Applications: Mid-volume retail, cosmetics, FMCG brands

- Advantages: Time-saving for fulfillment, customizable for branding

Common in automated packing lines and high-throughput order systems, this style offers both form and function.

7. Tab Lock Roll End & 3-Flap Tuck Boxes

Ideal for secure closure without glue or tape, especially in direct-to-consumer packaging.

- Tab Lock Boxes use side locks to hold structure without adhesives

- 3-Flap Tuck Boxes offer extra closure layers for increased stability

These are often used in gifting, promotional packaging, or high-end retail, where both function and aesthetics matter.

Box Style Selection Guide

| Box Style | Best For | Key Benefit |

|---|---|---|

| RSC | Bulk shipping, general goods | Most cost-efficient, stackable |

| FOL | Fragile, heavy products | Reinforced bottom/top, strong edges |

| RETF | Branded e-commerce boxes | Presentation-focused, tape-free |

| HSC | Storage and pick bins | Open top, versatile with lids |

| OPF | Books, garments, printed media | Low-profile, wraparound style |

| Tuck Top Auto Bottom | Cosmetics, retail kits | Quick assembly, ideal for automation |

| Tab Lock / 3-Flap Tuck | Gifting, premium retail boxes | Secure without tape, elegant user experience |

At POZI Packaging, we help clients evaluate not just box strength, but also packing workflow, product handling, branding needs, and cost per unit—delivering box styles that match your operational and marketing goals.

Quality Control Tests for Corrugated Packaging: Ensuring Performance from Production to Delivery

Corrugated packaging is only as reliable as the tests it passes—quality control ensures your boxes perform under pressure, literally.

Corrugated boxes undergo significant physical stress throughout their lifecycle—from factory handling and logistics stacking to international shipping and end-customer delivery. Without proper testing, even a well-designed box may fail when exposed to compression, shock, or puncture in real-world conditions.

To prevent product loss, damaged shipments, or rejected export batches, packaging manufacturers apply a series of standardized quality control tests that verify the strength, durability, and reliability of the corrugated material.

Here are the three most commonly used testing methods:

1. Edge Crush Test (ECT): Measuring Stack Strength

The ECT measures how much vertical pressure a corrugated board edge can withstand before collapsing.

- Purpose: Determines the load-bearing capacity of the box in stacked conditions

- Process: A vertical force is applied perpendicular to the edge of a sample board until it buckles

- Result: Reported in pounds per inch (e.g., 32 ECT), indicating stacking strength

ECT is particularly relevant for warehouse storage, palletization, and logistics optimization, where boxes are often stacked high. An underestimated ECT rating can result in bottom-layer failure and costly damages.

Common Use Cases:

- 32 ECT: Standard single-wall box for lightweight shipments

- 44–48 ECT: Double-wall boxes for heavier or export items

2. Flat Crush Test (FCT): Measuring Flute Resilience

The FCT evaluates how much pressure the corrugated fluting can handle before it is flattened.

- Purpose: Assesses flute structure’s ability to maintain cushioning under surface compression

- Process: A flat pressure is applied directly onto the board’s surface until the flutes collapse

- Relevance: Indicates the box’s ability to absorb shocks and resist deformation during transit

This test is important for fragile products, where the internal cushioning effect of the flutes is crucial to prevent breakage.

3. Mullen Test (Burst Test): Testing Puncture Resistance

The Mullen Test measures the force required to rupture the corrugated board using hydraulic pressure.

- Purpose: Evaluates overall tensile strength and durability under rough handling

- Measurement Unit: Pounds per square inch (psi) required to burst the board

- Typical Ratings: Ranges from 150 to 300 psi depending on the board composition

Mullen-rated boxes are often required for export markets, military use, or hazardous materials, where packaging regulations demand higher puncture and burst strength.

Why These Tests Matter in Real-World Applications

| Test | What It Protects Against | Use Case |

|---|---|---|

| Edge Crush Test | Collapse from stacking | E-commerce, warehouses, supply chain stacking |

| Flat Crush Test | Flute damage under pressure | Glassware, cosmetics, consumer electronics |

| Mullen Test | Tears, punctures, shipping abuse | Export packaging, B2B logistics, regulatory compliance |

At POZI Packaging, we rigorously test every corrugated structure through internal QC protocols and provide certified documentation when needed—especially for clients involved in international shipping, regulated industries, or fragile product categories.

These tests are not optional—they are essential for ensuring your packaging not only meets but exceeds performance expectations in transit and in storage.

Benefits of Corrugated Packaging: Why It Remains the Industry’s Top Choice

Corrugated packaging offers the ideal balance of strength, sustainability, and customization—making it the most trusted solution for manufacturers, retailers, and global logistics providers alike.

Across industries, corrugated boxes have become the default packaging solution for one key reason: they work. Their unique combination of multi-layered structure, material versatility, and scalable design makes them suitable for everything from fragile e-commerce shipments to heavy-duty export containers.

Let’s explore the key benefits in detail:

1. Exceptional Product Protection

Corrugated boxes are engineered to absorb shock, resist crushing, and maintain structural integrity throughout the supply chain.

The layered construction—fluted medium between flat liners—creates air pockets that cushion products from mechanical impact. This makes corrugated packaging ideal for:

- Fragile items (glass, ceramics, electronics)

- Items exposed to vibrations or drops in transit

- Stackable pallet shipments in warehouses

The board grade and flute type can be precisely matched to your product’s weight and fragility, ensuring that your goods arrive safe, intact, and professionally presented.

2. Highly Customizable for Product and Brand

Corrugated packaging can be engineered and printed to reflect both structural and visual needs.

From internal inserts and folding mechanisms to multi-color printing and premium surface finishes, corrugated boxes offer extensive flexibility:

- Custom die-cuts for form-fitting compartments

- Offset and flexo printing for high-impact branding

- Lamination, embossing, spot UV, and foil options for retail appeal

Whether you’re shipping industrial tools or luxury candles, corrugated boxes can be adapted to enhance functionality and customer experience.

3. Lightweight and Cost-Efficient

Corrugated packaging delivers protective strength without adding significant weight—helping reduce shipping and handling costs.

Compared to wood, plastic, or metal containers, corrugated boxes:

- Weigh less, lowering freight charges

- Can be flat-packed, reducing storage and warehouse space

- Require less energy to manufacture and recycle

This makes them ideal for cost-sensitive markets, especially where packaging is single-use or subject to frequent design updates.

4. Environmentally Friendly and Recyclable

Corrugated cardboard is one of the most sustainable materials in commercial packaging.

Most corrugated boxes today are made from 70–100% recycled fibers, and are:

- Biodegradable in natural conditions

- Recyclable through standard municipal systems

- Renewable, as kraft paper is typically sourced from managed forests

Additionally, corrugated board can be re-engineered for minimal material waste through smart dieline layouts and right-sizing strategies—helping your brand reduce its carbon footprint without compromising product protection.

At POZI Packaging, we offer FSC-certified corrugated solutions and help clients transition to plastic-free packaging alternatives aligned with ESG goals.

5. Scalable for Every Industry

Corrugated packaging can serve industries ranging from:

- E-commerce: Custom mailers, printed shipping boxes, subscription kits

- Retail & Luxury: Offset-printed rigid-style corrugated boxes with premium finishes

- Food & Beverage: Stackable cartons with moisture barriers or greaseproof coatings

- Industrial: Heavy-duty double/triple wall corrugated for large or hazardous goods

- Logistics: Pallet-ready configurations with clear BMC labeling for export

Its universal applicability means you don’t need to reinvent your packaging system as your business grows—corrugated scales with you.

Are There Any Drawbacks to Corrugated Packaging? Understanding the Limitations and How to Address Them

While corrugated packaging offers unmatched versatility and protective value, it’s important to understand its limitations—so you can design smarter, more cost-effective solutions.

No packaging material is perfect in every scenario. Corrugated cardboard, despite being a top-tier option in most industries, comes with certain drawbacks that must be acknowledged and planned for, especially in applications involving extreme environments, long-term storage, or ultra-low-margin product lines.

Let’s break down the most common challenges and how you can manage them effectively:

1. Susceptibility to Moisture and Weather Conditions

Corrugated board is inherently absorbent, making it vulnerable to water damage if not properly treated.

Uncoated corrugated boxes may lose rigidity, warp, or delaminate when exposed to:

- Humid storage conditions

- Rain during transit

- Cold-chain or frozen supply chains

Mitigation Strategies:

- Apply moisture-resistant coatings or lamination films

- Use PE-lined or waxed liners for refrigerated packaging

- Select plastic corrugated or hybrid materials for specific cold-chain use

At POZI, we offer water-resistant coatings and custom structural solutions for clients in the food, pharma, and agricultural sectors.

2. Higher Cost Compared to Low-End Packaging Alternatives

Corrugated packaging—especially when customized—can be more expensive than simple paperboard cartons or plastic bags.

Costs are influenced by:

- Paper raw material market fluctuations

- Added structural layers (double/triple wall)

- Custom die-cutting, printing, or coatings

- Freight costs due to larger unfolded size (for bulky boxes)

Mitigation Strategies:

- Use single-wall construction with smart inserts instead of double-wall

- Optimize box dimensions with right-sizing to reduce material usage

- Consolidate designs across SKUs to achieve economies of scale

- Choose standardized box styles with minor print variation to cut tooling costs

Our team at POZI helps you analyze cost-per-unit vs. protection level, so you can optimize packaging economics without compromising product safety or brand value.

3. Limited Longevity in Harsh Environments

Corrugated boxes are designed primarily for short- to medium-term protection—not for indefinite storage or exposure to high mechanical stress.

In long-term warehousing or rugged industrial handling, cardboard may:

- Soften over time

- Attract insects in improper storage

- Lose compression strength under prolonged vertical load

Mitigation Strategies:

- Rotate stock regularly

- Store in controlled environments

- Reinforce boxes with additional interior structures or edge protectors

If you’re looking for packaging that will be reused multiple times (e.g., returnable containers), corrugated may not be the most durable choice—but it remains optimal for one-way transit and display-ready logistics.

Balancing the Downsides with Strategic Packaging Design

Corrugated packaging isn’t flawless—but when used strategically, its limitations can be effectively managed through:

- Material optimization

- Protective coatings

- Functional inserts

- Right-size engineering

- Box-style selection based on use case

At POZI, we don’t just manufacture boxes—we help you think through real-world usage, shipping risks, and lifecycle costs, ensuring your packaging performs consistently across all environments.

Ready to Build Your Custom Corrugated Boxes? Let’s Get Started.

Choosing the right corrugated packaging isn’t just about material—it’s about aligning structure, protection, branding, and logistics into one cohesive solution that supports your business goals.

Whether you’re shipping electronics across borders, delivering subscription kits to consumers, or launching a new retail line, your packaging is more than just a box—it’s your first impression, your protective barrier, and your silent brand ambassador.

At POZI Packaging, we combine engineering precision with market insight to help you design corrugated packaging that fits your product, your process, and your identity.

Here’s what we offer:

- 🧩 Tailored Structural Engineering

We analyze your product’s weight, fragility, and shipment method to recommend the ideal flute type, wall structure, and box style. - 🎨 Custom Print & Branding Options

From single-color logos to full-surface offset printing with premium finishes—we help your box stand out on the shelf or doorstep. - 📦 Low Minimums & Scalable Production

Whether you’re a startup or an established brand, we offer flexibility with MOQ-friendly batch runs and full-scale production capacity. - 🌍 Sustainable Materials, Certified Solutions

FSC-certified, recyclable, and customizable to meet your ESG goals without compromising performance. - 🧪 Performance Testing & Export-Ready Packaging

All boxes are tested for ECT, burst strength, and stacking performance—complete with Box Maker’s Certificates (BMC) for customs and compliance.

Let’s Create Smarter, Stronger Packaging—Together

Tell us what you need: the product, the use case, the destination—and we’ll take care of the rest.

📩 Reach out today to speak with a packaging engineer, request dieline support, or get a free structural consultation and quote.

With POZI, your packaging does more than protect—it performs, presents, and propels your brand forward.