Quick Answer

Kraft paper boxes are one of the strongest, most cost-effective, and eco-friendly packaging solutions you can choose — they’re fully recyclable, look natural, and help brands show a commitment to sustainability without sacrificing durability or style.

What Are Kraft Paper Boxes?

Kraft paper boxes are packaging boxes made from kraft paper, a durable and naturally brown paper known for its high tear resistance and strength. The word “kraft” comes from the German word for “strength,” which is exactly what this material delivers.

Unlike ordinary paperboard, kraft paper is created through a chemical pulping process that preserves more cellulose fibers, making it tougher and more durable. This is why you’ll often see kraft paper used for shipping cartons, eco-friendly gift boxes, and recycled mailers — basically any application where you want a sturdy yet sustainable box.

Brands love kraft paper boxes because they offer a raw, natural look that instantly signals eco-friendly values to customers. They can be left plain for a rustic vibe or printed with bold designs and logos to create an affordable but impactful branded package.

In short, kraft paper boxes give you the best balance between strength, cost-efficiency, and sustainability — all wrapped up in a package that feels authentic.

How Is Kraft Paper Made?

Kraft paper is made using a special chemical pulping process called the Kraft Process. This method was invented in the 19th century and is still used today because it creates paper that’s stronger than regular paperboard.

Here’s how it works:

- Wood chips — usually from pine or bamboo — are cooked with a mix of water, sodium hydroxide, and sodium sulfide.

- This breaks down lignin, the sticky substance that holds wood fibers together, while keeping the long, strong cellulose fibers mostly intact.

- The result is a coarse, unbleached pulp that’s naturally brown — that’s raw kraft paper!

Because it keeps more of the original fiber strength, kraft paper is tough, tear-resistant, and perfect for heavy-duty packaging like corrugated cartons or rigid mailers. Some kraft paper is bleached for a clean white look, but the natural version is the most eco-friendly because it requires less processing and fewer chemicals.

This is why when you choose kraft paper boxes, you’re getting packaging made from a process that balances durability, sustainability, and cost.

Why Choose Kraft Paper Boxes?

Choosing kraft paper boxes isn’t just about cost — it’s about balancing durability, sustainability, and brand appeal better than many other packaging materials.

Here’s how kraft paper stacks up against other common options:

| Feature | Kraft Paper Boxes | White Paperboard Boxes | Plastic Packaging | Luxury Rigid Boxes |

|---|---|---|---|---|

| Strength | Strong, tear-resistant | Moderate | Flexible but prone to cracks | Very strong |

| Eco-Friendliness | 100% recyclable, biodegradable | Recyclable but may require more processing | Not biodegradable, hard to recycle | Can be recycled, depends on lamination |

| Cost | Cost-effective for all volumes | Moderate | Cheap per unit, but high impact | High production cost |

| Custom Printing | Natural look, bold or white print possible | Smooth surface, vivid colors | Limited print durability | Premium finishes, luxury feel |

| Best for | Eco-friendly brands, e-commerce, subscription boxes | Retail boxes, food sleeves | Single-use packaging | Premium gifting, high-end retail |

1. Strength & Protection

Kraft paper is naturally strong. The long fibers in the kraft pulp mean your boxes can handle heavier products and survive rough shipping conditions. This is why kraft paper boxes are often used for e-commerce shipping, food deliveries, and retail packaging that needs to stay intact.

2. Cost-Effective

Compared to luxury rigid boxes or plastic packaging, kraft boxes are affordable to produce in large or small quantities. You get a durable box that doesn’t break the bank — perfect for growing brands that want reliable packaging without overspending.

3. Sustainable & Recyclable

Today’s customers want to know their packaging won’t hurt the environment. Kraft paper boxes are 100% recyclable, biodegradable, and often made from recycled materials. This makes them a smart choice for brands that care about eco-friendly practices and want to communicate that clearly.

4. Versatile Branding Options

Don’t let the natural brown look fool you — kraft boxes can be custom printed with bold colors, white ink, or metallic foils to match your brand style. You can also add embossing, die-cut windows, or stickers to make them pop on the shelf.

In short, kraft paper boxes offer a balance of protection, price, sustainability, and flexibility that other packaging options struggle to match.

Takeaway: If you want packaging that’s sturdy, natural-looking, low-impact on the environment and still cost-effective, kraft paper boxes are hard to beat.

Common Uses for Kraft Paper Boxes

Kraft paper boxes are incredibly versatile — that’s why you’ll see them everywhere, from small handmade soap brands to global e-commerce stores. Here’s where they shine:

E-commerce Shipping & Subscription Boxes

Many online brands use kraft mailer boxes because they’re strong enough to protect products during shipping yet light enough to keep postage costs down. Subscription box companies also love the rustic, natural vibe that kraft paper delivers.

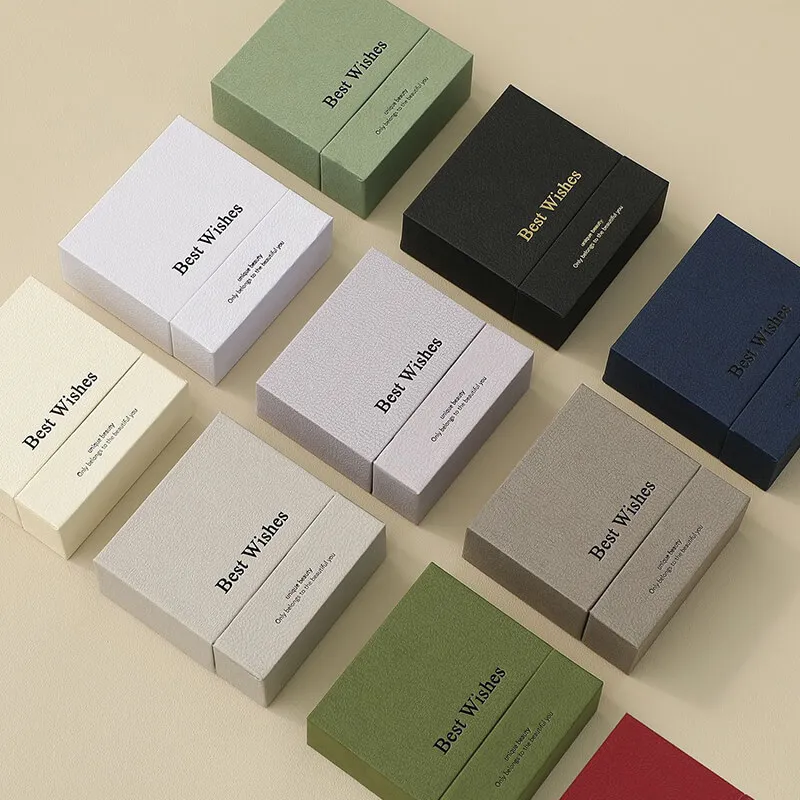

Retail Packaging & Gift Boxes

Kraft boxes are a go-to for eco-friendly gift packaging. Think candles, cosmetics, jewelry — anything where you want the packaging to feel warm, authentic, and low-waste. Add a ribbon or custom sticker, and you’ve got a gift-ready look without extra fuss.

Food & Beverage Packaging

From takeout boxes and bakery cartons to coffee sleeves and sandwich wraps, kraft paper is safe for food contact (when certified) and sends a clear message that your brand cares about sustainability.

Marketing Kits & Promotional Packaging

Brands use custom kraft boxes to create an unboxing moment for influencers or press kits. The natural look pairs well with bold printing, making your logo or campaign message stand out.

Product Inserts, Fillers & Protective Layers

Kraft paper isn’t just for the box itself — it’s perfect for wrapping products inside, adding cushioning, or even printing branded tissue to elevate the unboxing experience.

In short, kraft paper boxes fit any industry where you need affordable, strong, and recyclable packaging that doesn’t look cheap.

Customization & Printing Options for Kraft Paper Boxes

One of the best things about kraft paper boxes is how flexible they are when it comes to customization. You’re not stuck with a plain brown box (unless that’s the vibe you want). With the right design and finishing, you can create packaging that feels simple, premium, or bold — whatever suits your brand.

Printing Techniques

Even though kraft paper has a natural, slightly textured surface, it works well with a variety of printing methods. You can use simple one-color ink for a minimalist look or go for full-color printing with white ink underlays to make colors pop on the brown surface.

Common methods include:

- Flexo Printing: Great for larger volumes with straightforward graphics.

- Offset Printing: Ideal for detailed designs and high-quality color matching.

- Screen Printing: Works well for bold logos or short runs.

Finishing Touches

You can make kraft boxes stand out with finishing options like:

- Foil Stamping: Metallic or holographic foil details for a touch of luxury.

- Embossing/Debossing: Adds texture and a premium feel to logos or patterns.

- Spot UV Coating: Creates contrast with glossy highlights against the matte kraft surface.

- Die-Cut Windows: Show off your product inside while keeping the box protective.

- Custom Inserts: Secure fragile items with kraft paperboard dividers or trays.

Branding Made Easy

Custom kraft paper boxes help your brand look thoughtful and consistent. They can communicate eco-friendliness, simplicity, or sophistication — all while staying cost-effective. Plus, using soy-based inks and water-based coatings keeps your printing process more sustainable.

When done right, kraft packaging doesn’t just protect your product — it becomes part of the unboxing experience customers remember.

Cost Factors & MOQ for Kraft Paper Boxes

One reason so many brands choose kraft paper boxes is that they deliver good value — you get sturdy, eco-friendly packaging without a huge upfront investment. But like any custom packaging, a few factors affect your total cost.

Key Cost Factors

1. Box Size & Structure

Larger or more complex structures like magnetic rigid kraft boxes or multi-piece sets cost more than standard mailer or folding cartons.

2. Material Thickness & Layers

A single-wall kraft paperboard is cheaper than a double-wall or corrugated kraft option. The thickness you choose affects durability and price.

3. Printing & Finishing

Simple one-color flexo printing costs less than multi-color offset or special finishes like foil stamping, embossing, or Spot UV.

4. Quantity Ordered

Higher quantities mean lower cost per unit. This is because printing plates, die-cut tools, and setup costs get spread across more boxes. For short runs, digital or screen printing is more economical.

Typical Minimum Order Quantity (MOQ)

Most kraft box manufacturers have an MOQ to ensure production efficiency.

- For folding cartons or mailer boxes, MOQs usually start around 500 to 1,000 units.

- For rigid kraft gift boxes with complex finishes, expect a higher MOQ, often 1,000 to 3,000 units.

If you’re not ready for high volumes, start with a smaller batch to test your design and sizing first — then scale up as your brand grows.

Sampling & Prototyping

Always ask your supplier for a physical sample or digital prototype. This helps you double-check colors, print clarity, and box strength before committing to bulk production. It’s a small upfront investment that saves money on reprints later.

Key Takeaway

The total cost of kraft paper boxes is flexible — it depends on how custom you want to go and how many you need. But whether you’re a small business or an established brand, kraft packaging usually hits the sweet spot for price, quality, and sustainability.

Sustainability Benefits of Kraft Paper Boxes

If you want your packaging to send the right message about your brand’s commitment to the planet, kraft paper boxes are an easy win. Here’s why:

Made from Renewable Resources

Most kraft paper is made from sustainably managed forests, using fast-growing trees like pine or bamboo. Unlike plastic or mixed-material boxes, kraft paper comes straight from renewable raw materials.

Recyclable & Biodegradable

Kraft paper boxes can be tossed in the regular recycling bin. If they end up as waste, they biodegrade quickly — much faster than plastic or laminated materials. This means less landfill build-up and fewer microplastics in the environment.

Low Chemical Footprint

The kraft pulping process uses fewer bleaching agents than standard paperboard production. The result? Less water pollution and lower emissions.

Supports Circular Economy Goals

Many kraft boxes are made from a blend of virgin pulp and recycled fibers, closing the loop and giving old paper new life. Some brands even print their boxes with soy-based inks or water-based coatings to keep the entire supply chain greener.

Consumers Love Eco-Friendly Brands

Today’s shoppers want to feel good about what they buy. Choosing kraft paper packaging helps you stand out to customers who value sustainability — and they’ll remember you for it. A simple kraft mailer or gift box can do more for your brand’s reputation than you think.

How to Get Started with Custom Kraft Paper Boxes

You’ve learned about the benefits, options, and cost factors — so how do you actually make custom kraft paper boxes happen? Here’s a simple step-by-step to help you move from idea to delivery.

Step 1: Define Your Box Specs

Start by listing what you want:

- What size and shape do you need?

- Will it be a mailer box, folding carton, or rigid gift box?

- How much weight does it need to hold?

Knowing these details early makes the design and quoting process faster.

Step 2: Choose Printing & Finishes

Decide how you want your branding to appear.

- Simple single-color logo?

- Full-color printing with white ink?

- Any foil stamping, embossing, or die-cut windows?

These choices help you stand out while staying true to your budget.

Step 3: Request Samples or a Prototype

Ask your packaging supplier for a physical sample or digital proof. This is the best way to test durability, fit, and print quality. Don’t skip this — it saves you from expensive surprises.

Step 4: Place Your Order & Check MOQs

Once your design is approved, confirm your order quantity. Remember, larger runs bring your per-unit cost down. Double-check your supplier’s minimum order requirements so you’re not caught off guard.

Step 5: Plan for Shipping & Delivery

Finally, plan your production timeline and shipping. A good supplier will help you schedule your production slot, arrange packaging, and handle any customs or freight steps if you’re importing.

Pro Tip: Build a few extra weeks into your timeline, especially if you’re coordinating a launch or holiday campaign.

Ready to Start?

Working with an experienced kraft box manufacturer makes the entire process smooth. They’ll walk you through materials, print options, pricing, and samples — so you get exactly what you need without the headaches.

Ready to Make Kraft Paper Boxes Work for You?

Custom kraft paper boxes are one of the simplest ways to protect your products, elevate your brand image, and show your commitment to sustainability — all without breaking the bank.

Whether you’re shipping, gifting, or selling in retail, the right kraft box can help you stand out and build trust with customers who care about what’s inside and outside the box.

Need help getting started? Our team is here to guide you through design, sampling, and production — so you can launch packaging that’s strong, stylish, and eco-friendly from day one.

Get in touch today to request a custom quote or a free sample, and bring your kraft box ideas to life!

Table of Contents