Which Method is Right for Your Custom Packaging?

Choosing the right printing method can make or break the final look of your custom packaging. Whether you’re producing rigid boxes, folding cartons, or promotional bags, your printing choice directly impacts color accuracy, surface compatibility, unit cost, and production efficiency.

Offset printing and silk screen printing are two of the most commonly used methods in the packaging industry. While both can deliver professional results, they operate on different principles, perform best in different scenarios, and serve different business needs.

In this guide, we’ll break down how each technique works, compare their pros and cons, and help you decide which is best suited for your packaging project — whether you’re printing 500 boxes or launching a full retail rollout.

What is Offset Printing?

Offset printing, also known as offset lithography, is a widely used commercial printing technique in which ink is transferred from a metal plate to a rubber blanket, and then from the blanket onto the final printing surface — typically paper, cardboard, or packaging board. The term “offset” refers to the indirect nature of this process, where ink never touches the substrate directly from the plate.

This method relies on a series of metal plates, each representing a different color in the design, usually in CMYK color mode (cyan, magenta, yellow, and black). These plates are precisely aligned to apply layers of ink onto the material with exceptional consistency and sharpness.

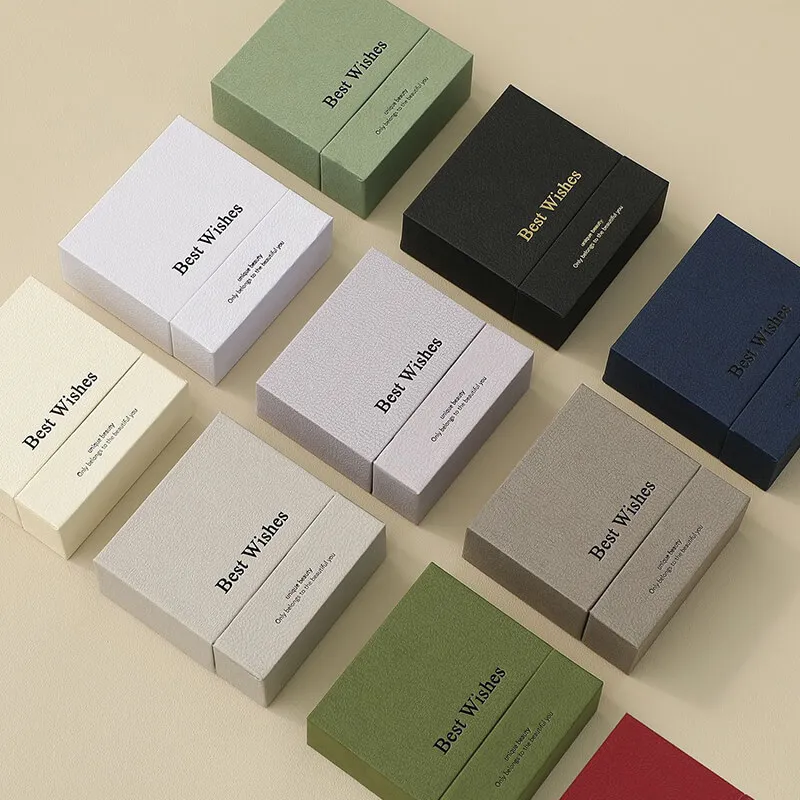

In the packaging industry, offset printing is commonly used for high-volume jobs such as folding cartons, rigid box wraps, paper sleeves, and marketing inserts. Its ability to deliver detailed graphics, consistent color reproduction, and low per-unit cost in large quantities makes it a preferred choice for brand owners seeking high-impact, scalable packaging solutions.

Advantages & Disadvantages of Offset Printing

Advantages of Offset Printing

Cost-Efficient for Large Volumes

Offset printing requires an initial setup for plate creation, but once in place, it becomes highly economical at scale. The cost per unit decreases significantly with higher print runs, making it ideal for mass production of packaging components such as product boxes, retail sleeves, and promotional inserts.

Superior Print Quality & Detail

This method delivers sharp, high-resolution graphics, consistent color tones, and clean lines. It excels in reproducing small text, intricate illustrations, and photographic images — critical for packaging that requires brand precision and professional presentation.

Versatile Material Compatibility

Offset presses can handle a wide range of substrates including coated/uncoated paper, cardboard, and synthetic sheets. It supports different finishes like matte, gloss, or textured papers, offering creative flexibility for brand differentiation.

Disadvantages of Offset Printing

High Setup Time & Cost

Each color requires a separate plate, which involves time and expense. This makes offset printing less practical for short runs or on-demand projects, where digital or silkscreen methods may be more efficient.

Limited Color Capabilities

Offset printing is primarily CMYK-based and does not support metallic, neon, or specialty inks without added cost and complexity. If your design calls for spot colors, foil accents, or Pantone-specific hues, screen printing or digital enhancements may be necessary.

Not Ideal for Variable Data Printing

Because offset uses fixed plates, it’s not suitable for personalization or packaging that requires changing elements (e.g., QR codes, serial numbers). Digital methods are preferred for such variable designs.

What is Silk Screen Printing?

Silk screen printing, also known as screen printing or serigraphy, is a printing method that involves pushing ink through a mesh stencil — called a screen — onto the surface of the packaging material. The areas not meant to be printed are blocked out on the screen, allowing ink to pass only through the open design.

Unlike offset printing, silk screen does not rely on pressure or heat transfer. Instead, it uses a manual or semi-automatic squeegee to press ink through the screen. Each color in the design requires a separate screen and must be applied individually in sequence.

Silk screen printing is especially valued for its vibrant color output, ink thickness, and versatility across surfaces. It’s commonly used for short-run packaging projects, promotional items, rigid boxes with specialty finishes, and even non-paper substrates such as fabric, plastic, glass, or metal. This makes it a popular choice for brands seeking tactile, bold visual effects and specialized applications.

Advantages & Disadvantages of Silk Screen Printing

Advantages of Silk Screen Printing

Excellent Color Saturation & Opacity

Silk screen printing delivers rich, vibrant colors with high ink coverage, making it ideal for packaging that needs strong visual impact. It supports specialty inks including metallics, fluorescents, and Pantone spot colors, which are difficult to achieve in offset or digital printing.

Compatible with Diverse Materials & Shapes

Unlike offset printing, silk screen can be applied to non-flat, curved, or textured surfaces. This makes it a go-to choice for printing on rigid boxes, cylindrical containers, glass bottles, fabric bags, and other promotional packaging items.

Cost-Effective for Small Runs

Because setup costs are relatively low and printing is done manually or semi-automatically, silk screen is more economical for low-volume or custom packaging projects, especially when color vibrancy is a priority.

Disadvantages of Silk Screen Printing

Labor-Intensive & Time-Consuming

Each color requires a separate screen and printing pass, which adds to production time. For multi-color designs, the process can be slower and more complex compared to offset or digital printing.

Lower Resolution for Fine Details

Silk screen printing is less suitable for small text, detailed graphics, or gradient transitions. The thicker ink layer can cause blurring or softness around edges, which may not meet precision requirements for certain premium packaging applications.

Inconsistent Results in Large Volumes

Due to its manual nature, silk screen printing may introduce slight variations between units, especially over long production runs. This limits its scalability when high-volume consistency is a key concern.

Offset vs. Silk Screen Printing: Side-by-Side Comparison

To help you decide which printing method is best for your packaging project, here’s a direct comparison of offset printing and silk screen printing across key performance factors:

| Feature | Offset Printing | Silk Screen Printing |

|---|---|---|

| Best For | High-volume runs with fine details and color consistency | Short runs with bold colors and specialty finishes |

| Setup Cost | High initial setup due to plate creation | Low to moderate setup, especially for single-color jobs |

| Unit Cost at Scale | Very low per unit cost for large quantities | Higher unit cost over large runs, but stable for small batches |

| Color Capabilities | CMYK only (spot colors possible with added cost) | Supports spot colors, metallics, fluorescents, and custom inks |

| Print Quality | Sharp resolution, ideal for fine text and complex graphics | Thick ink layer, less suitable for small text or fine lines |

| Surface Compatibility | Flat surfaces (paper, board, label stock) | Flat, curved, or textured surfaces (paper, plastic, glass, fabric, metal) |

| Turnaround Speed | Fast after setup; ideal for consistent, repeatable runs | Slower due to manual color layering, drying time, and stencil preparation |

| Design Flexibility | Best for static designs; poor for variable data | Good for custom layouts and surface variety, less ideal for detailed digital alignment |

Whether you’re printing thousands of folding cartons or creating a limited run of branded gift boxes, understanding these trade-offs helps you align printing methods with both creative vision and production goals.

Which Method Should You Choose for Your Packaging?

Choosing between offset printing and silk screen printing depends on your specific packaging needs — including quantity, material, design complexity, and color requirements. Here’s how to evaluate which method is right for your project:

Choose Offset Printing If:

You’re producing large quantities of identical packaging.

Your design involves small text, fine lines, or photographic images.

You need consistent, repeatable output with fast turnaround once setup is complete.

You’re printing on standard paperboard, folding cartons, or insert cards.

Choose Silk Screen Printing If:

You need bold, vibrant colors, including metallic or fluorescent inks.

Your packaging involves non-flat surfaces or materials like plastic, fabric, or glass.

You’re working with low to medium volumes or limited editions.

Your brand requires tactile finishes or a handcrafted look.

Still not sure which method fits your product best? A professional packaging supplier can help you weigh technical constraints against brand goals to determine the right printing solution — or even combine both techniques for layered visual effects.

Need Help with Custom Printing?

Whether you’re developing luxury rigid boxes, promotional kits, or retail-ready packaging, choosing the right printing method is key to balancing quality, cost, and visual impact. At POMAIS, we understand that every project has unique requirements — and we’re here to help you get it right from the start.

Our team offers comprehensive support across offset, silk screen, and digital printing, helping you match the ideal method to your materials, quantity, and branding goals. From dieline design and sampling to full production, we deliver precision and flexibility — even for complex or custom-shaped packaging.

Get in touch to request a free quote, explore material samples, or consult with our packaging specialists. Let’s bring your vision to life with printing that performs as beautifully as it looks.

Table of Contents

- Which Method is Right for Your Custom Packaging?

- What is Offset Printing?

- Advantages & Disadvantages of Offset Printing

- What is Silk Screen Printing?

- Advantages & Disadvantages of Silk Screen Printing

- Offset vs. Silk Screen Printing: Side-by-Side Comparison

- Which Method Should You Choose for Your Packaging?

- Need Help with Custom Printing?