In today’s competitive packaging industry, the terms “paperboard” and “cardboard” are often used interchangeably, yet they refer to two distinct materials with different structures, strengths, and purposes. For brand owners, importers, and packaging buyers, understanding these differences is more than just knowing the right terminology—it directly impacts packaging costs, brand image, and product safety.Whether you are creating a luxury folding carton for cosmetics or sourcing sturdy shipping boxes for e-commerce orders, choosing the right material can influence not only how your product is perceived on the shelf but also how well it survives the journey to the customer. This article breaks down the definitions, advantages, and best-use scenarios for each material, helping you make informed, cost-effective, and brand-appropriate packaging decisions.

What Is Paperboard?

Paperboard is a thick, paper-based material made from one or more layers of pressed fiber. It is typically less than 0.030 inches (0.76 mm) in thickness, yet has enough rigidity to maintain its shape while providing a smooth surface for printing. Unlike corrugated cardboard, which has a fluted middle layer, paperboard is solid and uniform in structure.

From a manufacturing perspective, paperboard can be single-ply (made from one solid sheet) or multi-ply (laminated layers for added strength). It is lightweight, easy to cut, crease, and fold, making it a preferred choice for folding cartons, sleeve packaging, and specialty retail boxes.

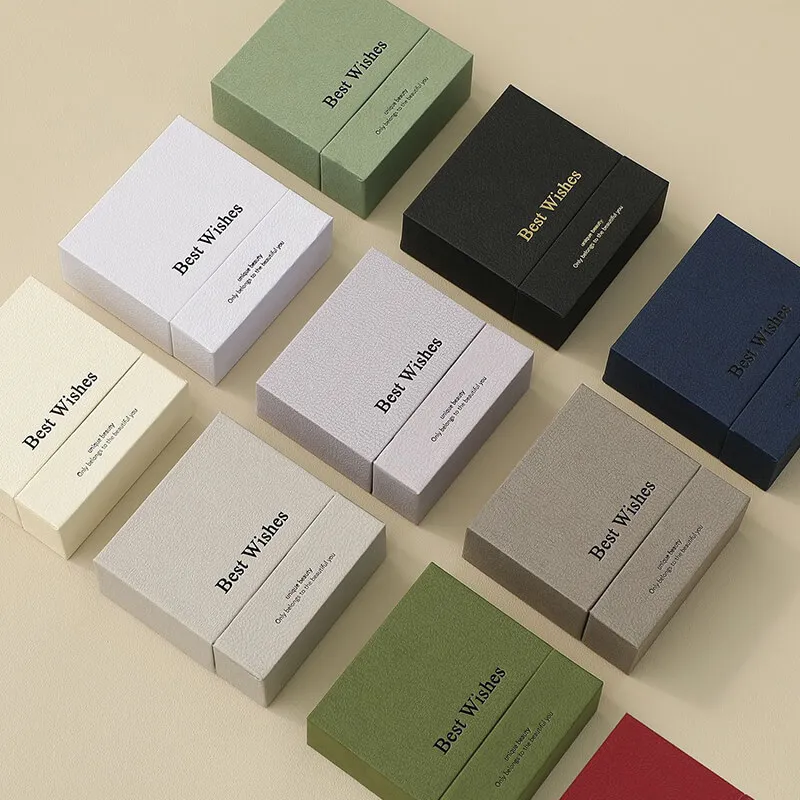

One of its biggest advantages is its printability—paperboard works exceptionally well with offset printing, digital printing, embossing, foil stamping, and specialty coatings, allowing brand owners to achieve high-end visual effects. This makes it an ideal choice for industries where brand presentation is as important as product protection, such as cosmetics, pharmaceuticals, gourmet foods, and premium gifts.

What Is Cardboard (Corrugated Board)?

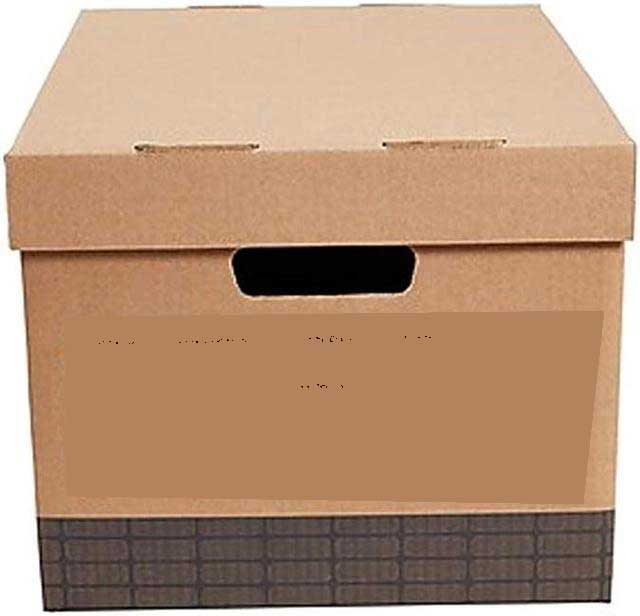

In packaging terminology, the word “cardboard” is often used casually to describe many paper-based packaging materials. However, in the manufacturing and logistics industry, it usually refers to corrugated board—a strong, multi-layer material made up of a fluted (wavy) inner layer sandwiched between two flat linerboards.

The fluting acts as a structural backbone, giving corrugated board its exceptional crush resistance and load-bearing strength. This makes it the preferred choice for secondary packaging (boxes that hold individually packaged products) and tertiary packaging (shipping boxes used for bulk transport).

Corrugated board comes in different grades and flute sizes (A, B, C, E, F, etc.), each offering a balance between cushioning, stacking strength, and printing surface quality. While its surface is generally less smooth than paperboard, it can still support printing methods such as flexographic printing, screen printing, and digital large-format printing—suitable for branding shipping boxes, subscription packaging, and e-commerce deliveries.

Its durability ensures products remain safe during long-distance transportation, withstanding stacking pressure, vibration, and environmental challenges like humidity or temperature fluctuations (especially when combined with protective coatings).

Key Differences Between Paperboard and Cardboard

Although both paperboard and corrugated cardboard are paper-based materials, their differences are significant enough to determine how, where, and why they are used in packaging. The following table highlights the most important distinctions:

| Feature | Paperboard | Cardboard (Corrugated Board) |

|---|---|---|

| Structure | Single or multi-ply solid sheet | Fluted inner layer between two linerboards |

| Thickness & Weight | Lighter, thinner (<0.030 inches) | Thicker, heavier, multiple flute grades |

| Strength | Supports lightweight retail goods | Handles heavy loads and stacking pressure |

| Printing Quality | Smooth surface for high-resolution printing | Rougher surface, limited to flexo/digital large-format |

| Applications | Folding cartons, luxury packaging, sleeve boxes | Shipping boxes, subscription boxes, bulk transport |

| Brand Appeal | Premium look & tactile finishes | Functional, industrial appearance |

| Cost Implication | Higher printing and finishing costs | Economical for bulk protective packaging |

| Sustainability | Easily recyclable, less material used | Fully recyclable, higher fiber content for strength |

This comparison shows a clear trade-off: paperboard offers superior printability and brand presentation, while corrugated cardboard provides unmatched structural strength for transport and storage. Many brands use both—paperboard for the retail display and corrugated cardboard for shipping—to strike a balance between aesthetics and protection.

When to Choose Paperboard

Paperboard is the go-to material when visual impact and brand storytelling are your top priorities. Its smooth, uniform surface makes it perfect for high-resolution printing, specialty finishes, and intricate die-cut shapes—all of which help create a premium unboxing experience.

You should consider paperboard if:

- Your product is lightweight – Ideal for cosmetics, confectionery, pharmaceuticals, and small electronics.

- Brand presentation matters – When shelf appeal influences purchase decisions, such as in luxury goods or specialty food packaging.

- You need design flexibility – Paperboard can be cut, folded, and glued into various shapes and styles, from folding cartons to sleeve packaging.

- You plan to use premium finishes – Processes like foil stamping, embossing, debossing, and spot UV are more effective on paperboard than on corrugated surfaces.

For example, a high-end perfume brand may use a folding carton made from coated paperboard to convey elegance, while a gourmet chocolate maker might choose uncoated kraft paperboard for a rustic, eco-friendly feel.

When to Choose Cardboard

Cardboard—more accurately, corrugated board—is the best choice when product protection and shipping durability outweigh visual presentation. Its multi-layered structure with a fluted core provides superior strength, cushioning, and resistance to crushing, making it ideal for transporting goods over long distances.

You should choose cardboard if:

- Your products are heavy or fragile – Such as glass bottles, electronics, or bulk packaged goods.

- You need strong stacking capability – For warehouse storage or container shipping where boxes are stacked high.

- You require impact and vibration protection – The fluted design absorbs shocks during handling and transit.

- You want a cost-effective shipping solution – Corrugated boxes are economical for large-scale distribution and bulk orders.

For instance, an e-commerce furniture retailer might rely on double-wall corrugated boxes for shipping chairs, while a beverage distributor may use custom-printed corrugated cases to safely transport bottled drinks across regions.

Can They Be Combined?

In many packaging strategies, paperboard and cardboard are not competitors—they work best as complementary materials. By combining the strengths of both, brands can achieve visual appeal on the retail shelf while ensuring durability during shipping.

A common approach is to use paperboard as the primary packaging—the folding carton or sleeve that customers see first when they open the box. This allows for premium printing, vibrant colors, and specialty finishes that enhance brand image. The outer shipping box, made from corrugated cardboard, then acts as a protective layer, safeguarding the product during transit.

This two-layer strategy is especially effective for e-commerce brands, luxury goods, and subscription services. For example:

- A skincare brand might place its glass serum bottles inside a printed paperboard folding carton, then ship them inside a corrugated mailer box.

- A gourmet food company may pack its delicately wrapped treats in paperboard boxes, then transport them in sturdy corrugated cartons for safe delivery.

Sustainability Considerations

Both paperboard and cardboard are made from renewable resources and are fully recyclable, making them popular choices for brands looking to reduce their environmental footprint. However, there are differences in how each material contributes to sustainability goals.

Paperboard generally uses less raw material for the same packaging volume, which can lower shipping weight and reduce carbon emissions during transportation. Many suppliers also offer FSC-certified paperboard or options made from post-consumer recycled content, aligning with eco-conscious brand values.

Cardboard (corrugated board), due to its higher fiber content and fluted structure, is extremely durable and can often be reused multiple times before recycling. In regions with strong recycling infrastructure, corrugated boxes have one of the highest recovery rates among packaging materials. Additionally, advances in water-based inks and recyclable coatings make corrugated packaging more environmentally friendly than ever before.

For brands, choosing the right material may involve balancing sustainability goals with functional needs. For example, reducing packaging layers may save material but could compromise product safety, while over-packaging might protect products but increase waste.

Conclusion

Choosing between paperboard and cardboard is not simply a matter of preference—it’s about matching the right material to your product’s journey from manufacturing to the customer’s hands.

If brand presentation and shelf appeal are critical, paperboard delivers unmatched print quality, design flexibility, and premium finishes that elevate the unboxing experience. If strength, durability, and protection are your top concerns, corrugated cardboard ensures your products arrive safely, even after long-distance shipping and handling.

For many brands, the optimal solution is a combination of both: paperboard for primary packaging to showcase the product, and cardboard for secondary packaging to safeguard it during transport. This approach strikes the perfect balance between aesthetics and functionality, ensuring customer satisfaction and brand consistency.

When planning your next packaging project, consider factors such as product weight, shipping method, branding goals, and sustainability targets. By making informed choices, you can reduce costs, enhance your brand image, and protect the environment—while delivering a great experience to your customers.