Home - Black Cardboard Jewelry Boxes

Custom Black Cardboard Jewelry Boxes

Custom Black Cardboard Jewelry Boxes pair luxury presentation with protective, brand-ready engineering. Built from 1.2–2.5 mm rigid paperboard and wrapped in deep black matte/soft-touch/anti-scratch finishes, they come in lid-and-base, magnetic book, drawer/sleeve, and collapsible forms with velvet/satin/flocked-EVA or paperboard inserts. Add your logo in foil/emboss/deboss/spot UV (optional edge gilding). Choose standard S/M/L footprints or fully custom L×W×H with ±1–2 mm tolerance; close with magnet, ribbon, or friction. FSC/recycled options and magnet-free builds available. Typical MOQs 500–2,000 and 15–30-day lead times. Share size, board, finish, branding, insert, closure, and quantity to receive samples, die-lines, and a firm quote.

Custom Black Cardboard Jewelry Boxes — Rigid, Branded & Gift-Ready

Premium black rigid jewelry boxes that balance timeless aesthetics, protective structure, and brand-forward customization. Built from rigid paperboard (greyboard) with refined black wraps and tailored inserts, they arrive retail-ready for rings, earrings, bracelets, necklaces, and curated gift sets—equally at home in luxury boutiques and DTC unboxing.

Quick spec chips

Rigid board 1.2–2.5 mm · Matte / Soft-touch / Anti-scratch · Foil / Emboss / Deboss / Spot UV · Velvet / Satin / Flocked EVA inserts · Magnetic / Ribbon closures · FSC / Recycled options · ±1–2 mm tolerance

Standard sizes (custom welcome)

- Small: 5 × 5 × 3 cm — rings, studs

- Medium: 9 × 9 × 3 cm — bracelets, small pendants

- Large: 15 × 15 × 3.5 cm — statement necklaces, layered sets

Styles & Structures

Choose a structure that fits the product, the display moment, and the unboxing flow.

Two-Piece Lid & Base (Lift-off)

- Best for: classic presentation, stackable inventory

- Strengths: simple, cost-efficient, clean branding surfaces

- Watch-outs: add finger notch or ribbon pull for easy opening

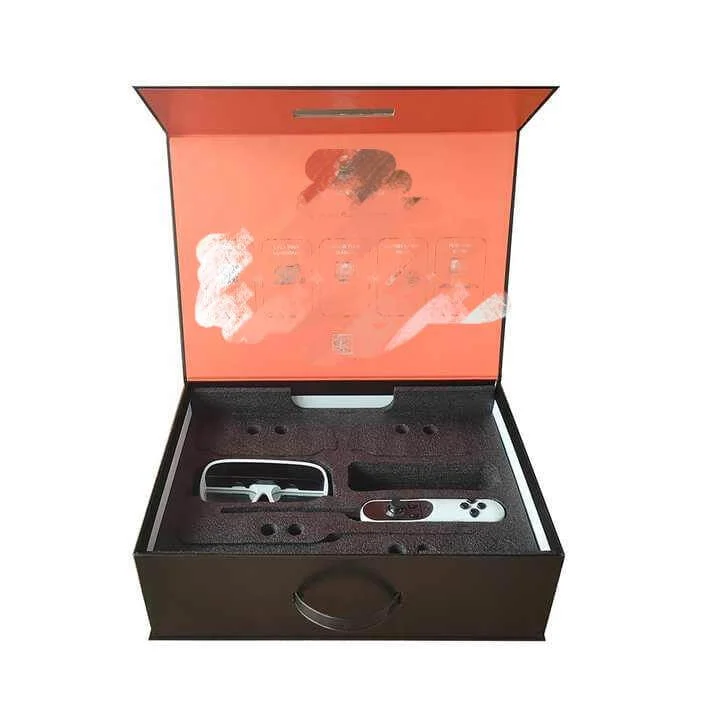

Book-Style / Magnetic Clamshell

- Best for: premium gifting, guided storytelling inserts

- Strengths: smooth magnetic closure, wide interior canvas

- Watch-outs: specify magnet count/placement to avoid over-pull

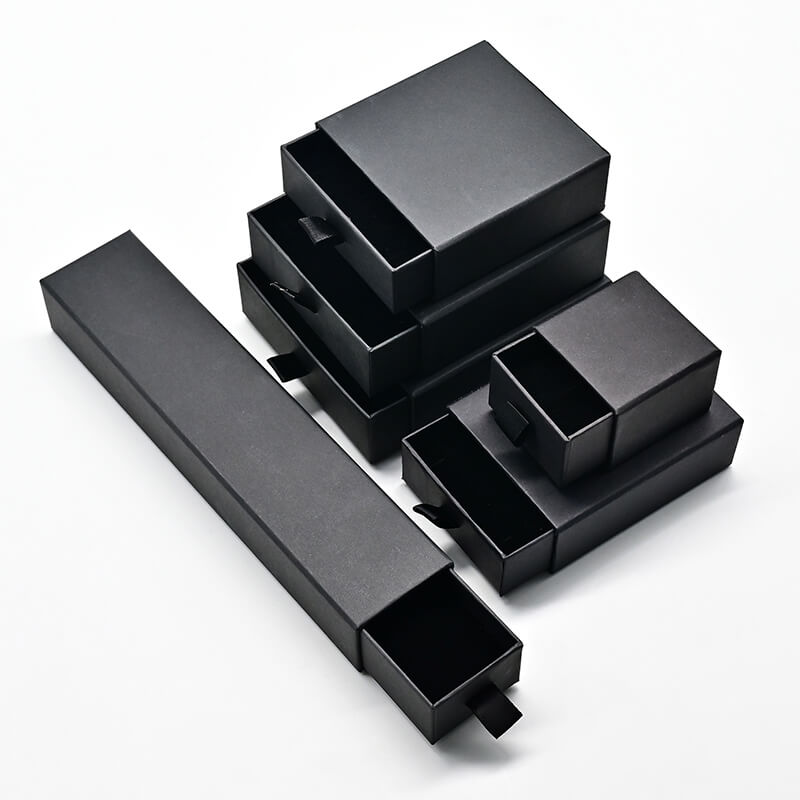

Drawer / Sleeve

- Best for: elegant reveal, retail displays with quick access

- Strengths: controlled glide, tray can host modular inserts

- Watch-outs: add ribbon pull; confirm sleeve friction for travel

Collapsible Magnetic Rigid

- Best for: saving freight/warehouse space at scale

- Strengths: folds flat; assembles in seconds with internal magnets

- Watch-outs: add anti-scuff wrap; validate corner strength

Size Map & Fit Guide (L × W × H)

Match the product to a box footprint and insert.

| Jewelry Type | Recommended Styles | Typical Footprints | Insert Suggestions |

|---|---|---|---|

| Ring / Studs | Lid & Base, Drawer | 50–70 × 50–70 × 30–40 mm | Flocked EVA ring slot / velvet pad |

| Earrings (drop/hoop) | Lid & Base, Book-Style | 70–90 × 70–90 × 30–40 mm | Card with slits + velvet / EVA |

| Bracelet / Bangle | Lid & Base, Drawer | 90–110 × 90–110 × 30–40 mm | Pillow insert / EVA channel |

| Pendant / Small Necklace | Lid & Base, Book-Style | 90–110 × 90–110 × 30–40 mm | Necklace card + foam recess |

| Statement Necklace / Set | Book-Style, Drawer | 140–160 × 140–160 × 35–45 mm | Custom multi-position insert |

Tolerances & fit

- Rigid boxes: dimensional tolerance ±1–2 mm.

- Leave 1–2 mm clearance around inserts; confirm chain slack so clasps don’t scuff.

Materials & Construction

- Rigid board (greyboard): 1.2 / 1.5 / 2.0 / 2.5 mm (thicker → stiffer walls & lid alignment).

- Black wraps: premium black specialty or black card 120–157 gsm; optional anti-scratch / anti-fingerprint coatings.

- Alternatives: for lightweight SKUs, a 300–400 gsm black paperboard folding carton variant.

- Inserts: velvet / suede / satin pads, flocked EVA (25–35 kg/m³), precision-cut foam, or paperboard trays for mono-material builds.

Closures & Unboxing

- Magnetic closure: single/double/four-point magnets; tune pull strength for retail vs. shipping.

- Ribbon tie / pull tab: satin or grosgrain; aids opening and adds a giftable cue.

- Friction fit: calibrated sleeve/liner tolerance for a smooth glide.

- UX touches: finger notches, lift ribbons under pads, card pocket for care/warranty.

Finishes & Branding

- Surfaces: matte, soft-touch, or anti-scratch (recommended for deep black).

- Brand marks: foil stamping (gold/silver/rose/black), emboss/deboss, spot UV accents, edge gilding for hero editions.

- Art guardrails: minimum line weight ≥0.3 mm; keep foil coverage ≤10–15% of face for a refined look; request drawdowns on live stock.

Protection & Durability

- Transport set-up: poly sleeve or tissue wrap per box, corner protectors for master cartons, optional desiccant.

- Common checks: rub/abrasion on edges (esp. soft-touch), magnet hold test, corner drop within outer shipper.

- Insert support: choose denser EVA for heavier stones/metal; avoid free play that causes micro-scuffs.

Retail Display & Sets

- Display-ready angles: book-style held at 30–45° with a hidden ribbon stay; drawer boxes with exposed pulls.

- Set builds: multi-cavity EVA/velvet trays, layered drawers, and dedicated card slots for certificates or QR authentication.

E-commerce Bundles

- Ready-to-Ship kit: box + velvet pouch + thank-you card + microfiber cloth + brand seal sticker.

- Mailing outer: right-sized mailer with easy-open strip; add foam corners or wrap for soft-touch finishes.

- Unboxing path: one-pull reveal; keep inner message above the product, not beneath.

Sustainability

- Fiber: FSC-certified options; recycled content on wraps and boards on request.

- Chemistry: water-based glues/inks; film-light or film-free soft-touch where feasible.

- Magnet-free option: ribbon/friction closures; paperboard or molded-fiber inserts for mono-material builds.

- On-pack guidance: plain-language disposal notes (“Remove magnet/ribbon before recycling” if applicable).

Ready-to-Order Configurations

Good — Lid & Base, matte wrap, 1-color foil logo, velvet ring/earring pad.

Better — Book-Style magnetic, soft-touch, foil + deboss, flocked EVA insert.

Best — Drawer + sleeve, soft-touch with foil + emboss, custom multi-cavity insert, ribbon pulls.

Cost, MOQ & Lead Time (Typical)

| Tier / Driver | Good | Better | Best |

|---|---|---|---|

| Unit cost signal* | $ | $$ | $$$ |

| Board & wrap | 1.5 mm + matte | 2.0 mm + soft-touch | 2.5 mm + soft-touch/anti-scratch |

| Branding | 1-color foil | Foil + deboss | Foil + emboss + spot UV |

| Insert | Velvet pad | Flocked EVA | Custom multi-cavity |

| MOQ | 1,000–2,000 | 500–1,000 | 500–1,000 |

| Lead time** | 15–20 days | 18–25 days | 20–30 days |

*Signals are relative; final pricing depends on size, finishes, insert complexity, and run length.

**After approvals; peak seasons may add time.

Savings levers: standardize footprints, share dies across SKUs, keep foil areas focused, choose mono-material inserts where feasible.

Production Process

Brief → White mockup (structure) → Finish swatches & foil drawdowns → Pilot run → Mass production → QA → Delivery

- Provide die-lines, logo vector (AI/PDF), Pantone/foil color targets, insert drawings.

- We validate fit, finish durability, and lid/tray alignment before scaling.

Customization Menu (Pick-to-Order)

- Style — Lid & Base / Book-Style Magnetic / Drawer / Collapsible

- Size — L × W × H (mm or inches)

- Board — 1.2 / 1.5 / 2.0 / 2.5 mm rigid

- Wrap — Matte / Soft-touch / Anti-scratch (deep black)

- Branding — Foil / Emboss / Deboss / Spot UV / Edge gilding

- Interior — Velvet / Satin / Flocked EVA / Paperboard tray (layout)

- Closure — Magnetic / Ribbon / Friction

- Sustainability — FSC / Recycled content / Magnet-free

- Packaging — Unit sleeve/tissue, master carton pattern, label specs

RFQ Checklist (Copy/Paste)

- Style & size (L × W × H): ___ × ___ × ___

- Board thickness: 1.2 / 1.5 / 2.0 / 2.5 mm

- Wrap & finish: matte / soft-touch / anti-scratch

- Branding: foil (color/area), emboss/deboss, spot UV

- Insert: velvet / satin / flocked EVA (layout & cutouts)

- Closure: magnetic (qty/placement) / ribbon (width/color) / friction

- Qty & deadline: ___ units by ___

- Sustainability: FSC? recycled %? magnet-free?

- Logistics: unit protection, master carton, pallet plan, ship-to

FAQ

Will soft-touch finishes show fingerprints?

Modern soft-touch with anti-fingerprint blends holds up well; for heavy retail handling, add anti-scratch or choose matte.

Can I avoid magnets for recyclability?

Yes—use ribbon or friction closures and paperboard inserts for a mono-material build.

How small can my foil logo be?

Keep strokes ≥0.3 mm and minimum letter height ≥3–4 mm for clean edges on textured wraps.

Can one insert work for several SKUs?

We can design modular cavities (e.g., ring pad + channel) to cover multiple SKUs in a single tray.

What tolerances should I expect?

Rigid boxes typically hold ±1–2 mm; we tune fit with insert compression and ribbon assists.

Are these boxes suitable for shipping?

Yes—pair with a mailer and protective wrap; we provide a “ready-to-ship” outer for DTC programs.

What’s the usual MOQ and lead time?

MOQs 500–2,000 depending on spec; lead times 15–30 days after approvals.

Conclusion

A single system that does it all: luxury black finish, rigid protection, tailored inserts, and brand-defining details—optimized for retail display and DTC unboxing.

Ready to elevate your jewelry line?

Send your L×W×H, board thickness, finish & branding, insert layout, closure type, and quantity. We’ll return samples, die-lines, and a firm quote aligned to your launch date.