Home - Jewelry Packaging with Logo

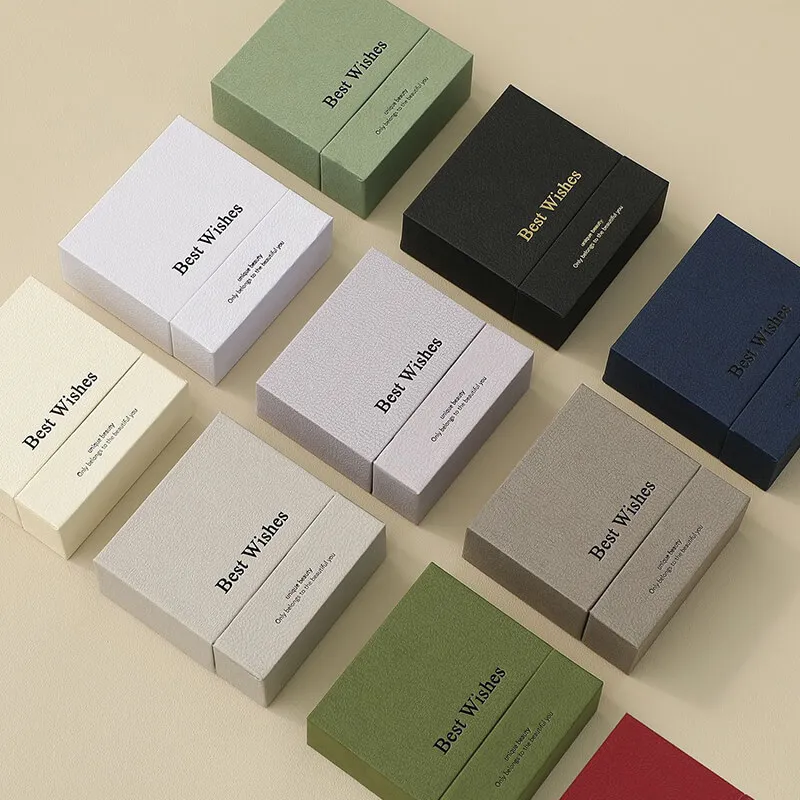

Custom Jewelry Packaging with Logo

We manufacture custom jewelry packaging with your logo that protects finishes and elevates unboxing. Choose rigid lift-off, drawer, book-style magnetic, sleeve-and-tray, or folding tuck. Pair with flocked foam or velvet inserts, Pantone-matched print, and premium finishes. We size every box to your SKUs and supply documented QC for frictionless receiving. FSC options and global delivery available.

Value in brief

- Structures: rigid two-piece, drawer, book-style magnetic, sleeve & tray, folding tuck; optional cellulose window

- Brand finishes: foil, emboss/deboss, soft-touch (anti-scuff), matte/gloss lamination, spot UV

- Speed: dielines on request • samples 5–7 days • production 10–18 days

What are the options at a glance?

| Category | Options (tunable) |

|---|---|

| Styles | Rigid two-piece · Drawer · Book-style magnetic · Sleeve & tray · Folding tuck · Windowed |

| Inserts | Flocked foam · Velvet pad · Satin pillow · Paperboard riser · Microfiber pouch |

| Materials | Greyboard 1.5–2.5 mm (rigid) · 300–400 gsm SBS/C1S (folding) |

| Printing | CMYK + Pantone; white ink on dark stocks; ΔE targets across runs |

| Finishes | Soft-touch (anti-scuff) · Matte/Gloss lamination · Foil · Emboss/Deboss · Spot UV |

| Docs | Spec sheet · QC photos · Pack photos · Pallet map |

How do you choose the right structure?

Rigid Two-Piece (Lift-Off) — Classic gift experience, balanced lid friction, ideal for premium lines.

Drawer (Ribbon Pull) — Shelving-friendly, smooth reveal, easy to open with gloves.

Book-Style Magnetic — Clean spine, wide branding area, stable closure for VIP kits.

Sleeve & Tray — Minimal look, great for collaborations and color collections.

Folding Tuck — Cost-efficient for large volumes, ships ultra-flat, quick set-up.

Windowed (Cellulose) — Retail visibility without losing recyclability messaging.

What size fits your SKUs?

| Type | Common internal sizes (mm) | Presentation height | Retainers | Tolerance |

|---|---|---|---|---|

| Single pair | 165–185 × 70–85 × 55–70 | 15–25 mm | Bridge & temple retainers | ±1.0–1.5 mm |

| Dual set | 200–230 × 120–140 × 60–80 | 15–25 mm | Dual cavities + pouch bay | ±1.0–1.5 mm |

| Travel kit | 220–260 × 150–180 × 60–90 | 20–30 mm | Cavity + care-card slot | ±1.0–1.5 mm |

Send frame dimensions and desired display height—we’ll return tuned dielines.

How do inserts protect and present your jewelry?

| Insert | Protection | Look & feel | Best for | Notes |

|---|---|---|---|---|

| Flocked foam | Form-fit retention; anti-slip | Fine, velvety surface | Premium frames; irregular shapes | CNC cavities; flock colors |

| Velvet pad | Scratch prevention | Classic gift aesthetic | Singles & sets | Add slits/pins |

| Satin pillow | Soft support | Romantic, gift-ready | Seasonal kits | Optional ribbon |

| Paperboard riser | Lightweight lift; recyclable | Minimal, brand-first | Cost-sensitive lines | Pair with belly band |

| Microfiber pouch | Scratch/clean; utility | Functional add-on | Travel kits | Fits in tray bay |

How do we keep your logo consistent?

- Color control: CMYK + Pantone with ΔE targets; drawdowns for blacks and metallics

- Readability: reversed type ≥ 8 pt; minimum line 0.4–0.5 mm

- Codes: barcodes/QR on matte panels; quiet zone ≥ 2.5 mm

- Finishes: soft-touch (anti-scuff for dark areas), matte/gloss lamination, foil, emboss/deboss, spot UV (away from folds and code areas)

- Interior branding: lid prints for care, authenticity, or QR journeys

What materials and claims can you make?

- Boards: greyboard 1.5–2.5 mm (rigid); 300–400 gsm SBS/C1S (folding)

- Windows: cellulose windows available; plastic-free narrative compatible

- Adhesives/inks: low-odor systems to protect coatings and finishes

- Claims: recyclable paper systems; FSC options; claims aligned with your selected films, liners, and inserts

How do you ship safely for DTC?

- Pair the inner logo gift box with a matched corrugated mailer (E/B/EB) for drops and surface rub.

- We supply pack photos, carton counts, and pallet maps for 3PLs and retail DCs.

- Transit checks typically include 0.6–0.9 m drop profiles and finish abrasion tests.

How do we validate quality?

- Documentation: spec sheet, QC photos, pack photos, pallet map

- Checks: dimensions & squareness, lid-fit cycles, insert pull-test, rub/scuff, ΔE color variance

- Statements: materials and finish statements provided with samples (we execute your legal text; no legal advice offered)

What are the technical specs?

| Category | Spec (typical; tunable) |

|---|---|

| Rigid boards | Greyboard 1.5–2.5 mm wrapped in coated/kraft/textured papers |

| Folding boards | 300–400 gsm SBS/C1S with lamination/varnish |

| Finishes | Soft-touch (anti-scuff), matte/gloss, foil, emboss/deboss, spot UV |

| Printing | CMYK + Pantone; white ink on dark stocks |

| Tolerances | Box height ±1.0–1.5 mm; lid fit tuned to wrap thickness |

| Options | Cellulose window; interior lid print; ribbon pulls; belly bands |

| Deliverables | Dielines · Spec · QC photos · Pack photos · Pallet map |

How the project runs end-to-end

Brief → Dielines → Artwork preflight → Samples 5–7 days → Approvals → Production 10–18 days → QC & pack photos → Delivery (FOB/CIF/DDP)

What is the MOQ and how do we price?

- MOQ: typically 1,000–3,000 per size/style (mixed sizes permitted)

- Pricing: based on structure, insert, finish stack, and quantity tiers; quote returned with timeline and packing plan

Why choose POZI for logo packaging?

- Unified dieline families that scale SKUs fast across collections

- Anti-scuff blacks and textured papers with controlled ΔE across runs

- One supplier for gift boxes and optional DTC mailers, with photo-verified packouts

- FSC paper options and recyclable constructions end to end

FAQ

Can you match our brand black and foil tone?

Yes. We provide Pantone drawdowns and foil swatches, then hold ΔE targets through production.

Which insert best protects premium coatings?

Flocked foam with bridge/temple retainers gives stable positioning and scratch resistance.

Can we add a window and keep recyclability?

Use a cellulose window and paper-based wraps; we align claim language with your materials.

Will soft-touch scuff in shipping?

We specify anti-scuff recipes and recommend a corrugated mailer for DTC.

How small can microcopy and barcodes go?

Reversed microcopy ≥ 8 pt; minimum line 0.4–0.5 mm; barcode quiet zones ≥ 2.5 mm on matte panels.

What artwork files do you need?

Vector AI/PDF with outlined fonts, 3 mm bleed, Pantone references, and finish layers.

Request Dielines & a 24-Hour Quote

Send your SKU dimensions and preferred finish stack today. We will return dielines, pricing tiers, and a dated sampling/production plan within one business day.