Home - Paper Shopping Bags with Logo

Custom Paper Shopping Bags with Logo

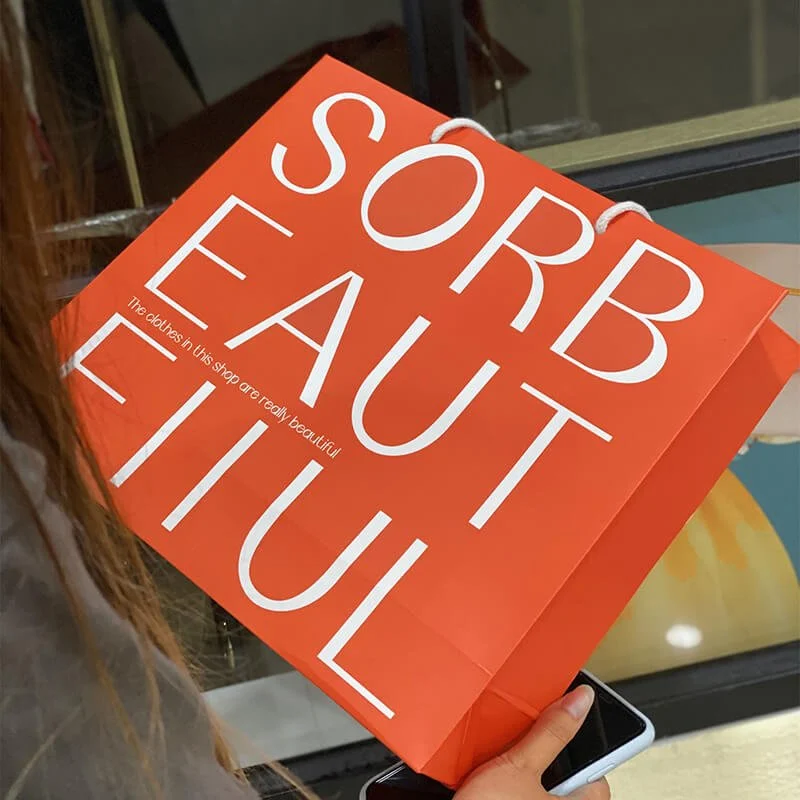

Branded, Retail-Ready Paper Bags That Turn Every Purchase Into Brand Exposure

When I produce paper shopping bags with logo, I treat them as a front-line brand asset—not a commodity. The right branded bag should do three things at once: carry reliably, photograph well, and keep your logo visible long after the customer leaves your store. That is why I build each program around material fit, paper thickness, print control, handle performance, and finishing durability—then lock everything with sampling before mass production.

What You Get: A Logo Bag Program, Not Just a One-Time Order

I structure your custom paper shopping bags with logo as a repeatable system you can scale across stores, seasons, and SKU lines:

- Material selection aligned with your positioning (natural kraft, coated paper, art paper, recycled paper)

- Paper thickness planning for the right balance of stiffness, feel, and carrying confidence (80–250gsm)

- Print standardization (CMYK + Pantone matching, optional screen printing and foil stamping)

- Handle engineering by use case (twisted paper, flat paper, die-cut, cotton rope, ribbon)

- Finishing menu to control scuffing and elevate perceived value (gloss/matte lamination, spot UV, embossing, debossing)

- Sustainability options available for eco-focused markets (FSC-certified, recyclable, biodegradable materials; soy-based inks optional)

If you also need a consistent storage workflow, I recommend pairing your bag program with paper shopping bag storage so bags stay flat, clean, and size-sorted in your backroom.

Product Specs at a Glance

| Attribute | Available Options |

|---|---|

| Bag Materials | Kraft Paper, Coated Paper, Art Paper, Recycled Paper |

| Paper Thickness | 80gsm–250gsm |

| Size Options | Small / Medium / Large / Custom |

| Printing Techniques | Offset CMYK, Pantone Matching, Screen Printing, Foil Stamping |

| Handle Types | Twisted Paper, Flat Paper, Die-cut Handles, Cotton Rope, Ribbon |

| Finishing Options | Gloss/Matte Lamination, Spot UV, Embossing, Debossing |

| Eco-Friendly Features | FSC-certified, Recyclable, Biodegradable Materials |

| MOQ | 1,000 units per customized order |

Why Logo Paper Shopping Bags Convert Better Than Generic Bags

A logo bag functions like a moving billboard. Every customer becomes a brand carrier, and that visibility compounds—especially in malls, event venues, and high-footfall retail streets. I focus on making that exposure “clean”: crisp printing, consistent color, and a bag that holds its shape so your logo looks premium, not distorted.

Materials & Paper Thickness: How I Match Feel, Durability, and Price Point

I keep material selection practical. Your bag should match the moment it appears in: luxury retail requires different “hand-feel” than a promotional giveaway.

Material guide (simple, buyer-friendly)

| Material Option | Best For | What You Gain | What I Watch For |

|---|---|---|---|

| Kraft Paper | Natural/eco positioning, boutiques, gift shops | Strong brand story, tactile feel | Finish strategy if you need higher scuff resistance |

| Coated Paper | High-color retail graphics | Sharper image performance | Surface protection planning for heavy handling |

| Art Paper | Premium look, gifting, launches | More “luxury” appearance | Controlled finishing so it stays clean in transit |

| Recycled Paper | Sustainability-first programs | Strong eco messaging | Confirm print expectations and thickness needs |

Thickness planning (80–250gsm)

I use thickness to control structure and perceived value. Lighter paper works for lightweight products and event distribution; heavier paper supports premium retail and higher-carry confidence. Your final thickness depends on bag size, handle type, and what you pack inside.

For heavier retail use, you may also want to compare with heavy duty paper shopping bags to align specs across your range.

Printing & Color Control: Making Your Logo Look Consistent Everywhere

If you operate multiple stores or seasonal campaigns, brand consistency is non-negotiable. I typically recommend:

- Offset CMYK for full-color graphics and high-volume efficiency

- Pantone matching when strict brand colors are required

- Screen printing for bold, minimal designs with strong ink presence

- Foil stamping when you want premium “signal value” (gift, luxury, jewelry)

If your brand also uses rigid gift packaging, you can align print tone and finishing across your bag and box program through custom printed boxes.

Handle Options: Performance + Brand Impression

Handles are where bags fail first—and also where customers “feel” quality first. I offer multiple handle types so you can optimize both function and appearance:

| Handle Type | Best Fit | Brand Effect |

|---|---|---|

| Twisted Paper | Most retail programs | Clean, classic, cost-effective |

| Flat Paper | Fashion and boutiques | More premium look, comfortable grip |

| Die-cut Handles | Lightweight items, promos | Minimalist, fast handling |

| Cotton Rope | Premium retail, gifting | Strong luxury signal |

| Ribbon | Gift-focused programs | High-end, decorative finish |

When needed, I also plan reinforcement options (base support, handle anchoring approach) to keep the carrying experience reliable—especially for larger sizes.

Finishing Options: Protect the Print, Upgrade the Shelf Presence

Finishing is not only decoration. In real retail handling, finishing is how you reduce scuffing and keep the bag looking new.

- Gloss or matte lamination for surface protection and consistent appearance

- Spot UV to highlight logo elements and improve “premium touch”

- Embossing / debossing for tactile branding that feels expensive

If you want a complete premium set, I typically align bag finishing with luxury paper shopping bags so your brand presentation stays coherent across channels.

Sustainability Options

If sustainability is part of your value proposition, I keep it concrete and procurement-friendly:

- FSC-certified paper options available upon request

- Recyclable and biodegradable material choices to fit local market expectations

- Soy-based ink option for reduced environmental impact positioning

- Recycled paper available for eco-led campaigns

Suitable Industries & Applications

I design logo bag programs to match how customers actually buy and carry products:

- Retail & Boutiques: stronger brand recall and repeat exposure

- Jewelry & Accessories: premium presentation that supports higher ticket value

- Beauty & Skincare: clean branding and elevated unboxing feel

- Corporate Events: consistent logo visibility across giveaways

- Food & Beverage: suitable material choices for cafés, bakeries, gourmet retail

Size Selection: What I Need to Recommend the Right Bag

Instead of guessing “small/medium/large,” I recommend sizing based on your product and packing method. If you send me the following, I can propose a practical size set:

- Product dimensions or typical order composition

- Preferred bag shape (tall vs wide presentation)

- Handle type requirement

- Target paper thickness range

- Retail vs event vs mixed use

Simple format you can send: W × G × H (Width × Gusset × Height) in inches or cm, plus estimated monthly volume.

Production & Delivery: How I Move You From Concept to Bulk

I keep the workflow structured so you can launch confidently:

- Requirements alignment: material, size, print standard, handle and finishing goals

- Design support and proofing: digital proof and optional physical sampling (typical sampling turnaround 5–7 days)

- Bulk manufacturing: stable output with in-process checks

- Quality assurance: inspections against confirmed specs

- Logistics: secure packing and global delivery options; typical bulk lead time is 10–15 business days after sample approval

MOQ for customized wholesale programs typically starts at 1,000 units per design.

Quality Control I Prioritize

For logo bags, QC is not just “no defects.” It is brand consistency at scale. I focus on:

- Color consistency (Pantone alignment where required)

- Handle attachment reliability and finishing cleanliness

- Surface protection performance (lamination/spot UV consistency)

- Dimensional consistency so bags stack well and store cleanly (especially if you use paper shopping bag storage)

FAQs

Can you exactly match my brand colors?

Yes. I support Pantone color matching in addition to CMYK so your brand colors stay consistent across runs.

What’s the turnaround time for customized orders?

For most programs, bulk production is 10–15 business days after sample approval. If you need a faster timeline, I will recommend a print/finishing path that fits your schedule.

Do you offer samples before mass production?

Yes. I can provide digital proofs and physical samples, with a typical sampling turnaround of 5–7 days depending on complexity.

Are these bags eco-friendly?

Eco options are available, including FSC-certified paper choices and recyclable/biodegradable materials. I can also discuss soy-based ink options based on your market needs.

What is your MOQ for logo paper shopping bags?

Standard MOQ is 1,000 units per customized order. If you have multiple SKUs, I can structure the program to minimize complexity while keeping branding consistent.

What printing techniques can you support?

I support offset CMYK, Pantone matching, screen printing, and foil stamping. I will recommend the right method based on your artwork style and the look you want on shelf.

Which handle should I choose?

If you need a safe default, twisted paper handles work well for most retail. For premium gifting, cotton rope or ribbon is often the right signal. I will align the handle choice with your bag size and paper thickness so it carries reliably.

Can you help if my design files are not final?

Yes. I provide design support and can help refine your logo and layout into a print-ready file.

Can you add premium finishes?

Yes. Gloss/matte lamination, spot UV, embossing, and debossing are available to improve durability and perceived value.

Can I align my bags with other packaging items?

Yes. Many brands keep their presentation consistent by aligning bags with custom printed bags programs and complementary packaging such as custom printed boxes or premium gift packaging.