Home - Reverse Tuck Folding Cartons

Custom Reverse Tuck Folding Cartons

If you want folding cartons that pack fast, present cleanly on shelf, and stay consistent across repeat orders, reverse tuck folding cartons are a reliable choice. With POZI Packaging, you can specify the exact board, structure, printing, and finishes you need—then scale production with stable QC and export-ready delivery.

Best for: cosmetics, personal care, supplements, food dry goods, small electronics, and retail-ready SKUs that require efficient packing and a professional front-panel presentation.

Fast Quote Checklist

- Carton size (L × W × H) + product weight (approx.)

- Board type preference (SBS / WLC / kraft) + target gsm

- Tuck direction requirement (reverse tuck) + opening preference (top/bottom)

- Printing: CMYK or Pantone + coverage level (light / medium / heavy)

- Finishes: matte/gloss/soft-touch + spot UV/foil/emboss (if any)

- Add-ons: window, tear strip, tamper evidence, inserts/dividers (if any)

- Quantity per SKU + destination country + target delivery window

| Spec Area | Standard Options You Can Configure |

|---|---|

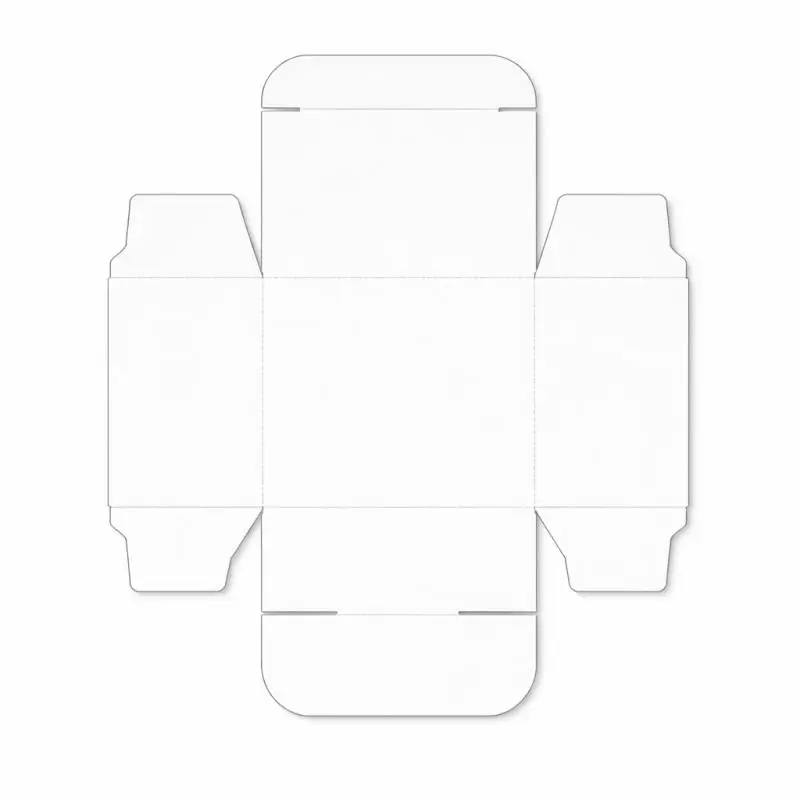

| Carton type | Reverse tuck end (RTE) folding carton; custom dielines supported |

| Board options | SBS (premium white) • WLC/CCNB (cost-efficient) • kraft paperboard (natural look) |

| Board weight (gsm) | Typical ranges include 250–400gsm depending on size, product load, and shelf goals |

| Printing | CMYK offset • Pantone matching • digital options for short runs (project-based) |

| Finishes | Matte / gloss • soft-touch (premium) • spot UV • foil stamping • emboss/deboss |

| Structural features | Reverse tuck ends • glue seam • optional dust flaps (dieline-dependent) |

| Functional add-ons | Window patch (project-based) • tear strip • tamper evidence • inner print |

| Compliance-friendly layout | Multi-language panels, barcode area planning, warning/ingredient panels (artwork-based) |

| MOQ | Project-based; depends on size, board, printing coverage, and finishes |

| Sampling | Plain sample or printed sample (timeline depends on artwork and finishing) |

| Mass production | Lead time depends on complexity and schedule; program-based reorders are typically faster |

| Export packing | Master carton + pallet options; label/marking support for international shipping |

What Is a Reverse Tuck End (RTE) Carton?

A reverse tuck folding carton is a folding carton structure where the top and bottom tuck flaps fold in opposite directions. This format is widely used because it is easy to assemble, looks clean on shelf, and provides a predictable opening experience.

You typically choose RTE cartons when you want:

- Efficient packing for medium-to-high volume runs

- A tidy retail appearance with controlled panel alignment

- A structure that works well with common paperboard and premium finishes

Why Reverse Tuck Works for Retail Programs

Reverse tuck cartons help you balance speed, presentation, and cost control—especially when your packaging must look consistent across multiple SKUs.

Operational efficiency

- Straightforward assembly for manual packing lines

- Repeatable dieline behavior for large-volume production

Shelf presentation

- Clean front panel and strong “box geometry” when board and crease depth are properly tuned

- Works well with premium finishes that help your product stand out

Brand consistency

- Easier to standardize a family look across multiple sizes and variants

- Predictable print-to-cut alignment when artwork is planned correctly

Materials and Board Selection

Your board choice defines stiffness, print quality, and the “feel” customers associate with your brand. The right selection also reduces issues like cracking on folds or scuffing in transit.

SBS (Solid Bleached Sulfate)

Choose SBS when you want a premium, bright-white surface and high-quality printing. SBS is common for cosmetics, skincare, and premium retail products where color accuracy and finish performance matter.

WLC / CCNB (White-Lined Chipboard)

Choose WLC when you need strong value at scale while still maintaining a clean printed surface. This is frequently selected for mass retail and high-volume programs where cost control is a priority.

Kraft Paperboard

Choose kraft when you want a natural, eco-forward aesthetic. Kraft works well with minimalist branding and can support strong differentiation when you use controlled ink coverage and clean layout design.

Board selection guidance that prevents problems

- For large cartons or heavier products, you typically need higher stiffness to keep panels flat and corners sharp

- For heavy coverage printing or premium finishes, you need a board and coating strategy that resists scuffing and preserves visual quality

- For tight folds, crease design and material selection reduce the risk of cracking on edges

Printing and Finishes That Sell on Shelf

You can treat reverse tuck cartons as either a cost-efficient retail pack or a premium presentation box—depending on the printing and finishes you specify.

Printing Options

- CMYK offset printing for full-color graphics and consistent retail presentation

- Pantone matching when brand color accuracy is critical across multiple SKUs

- Digital short-run support when you need prototypes, test batches, or seasonal variants (project-based)

Finish Options and When to Use Them

- Matte / gloss for classic retail presentation and product line consistency

- Soft-touch for premium feel (best for brands that want “luxury tactile” positioning)

- Spot UV for contrast highlights, logo emphasis, and visual hierarchy

- Foil stamping for premium brand cues and strong shelf pop

- Emboss/deboss for tactile branding without relying only on ink coverage

Practical note for real-world distribution

If your cartons will face friction in master cartons, long-distance shipping, or frequent handling, finish selection should balance aesthetics with scuff resistance.

Reverse Tuck vs Straight Tuck Folding Cartons

If your team is deciding between reverse tuck and straight tuck, this quick comparison helps you choose the most efficient structure for your specific product and packing workflow.

| Decision Factor | Reverse Tuck (RTE) | Straight Tuck (STE) |

|---|---|---|

| Opening direction | Top and bottom tucks fold in opposite directions | Top and bottom tucks fold in the same direction |

| Shelf presentation | Strong retail standard, versatile across categories | Often preferred when you want a consistent opening direction aesthetic |

| Packing workflow | Commonly used for efficient, repeatable packing | Works well when your pack line benefits from same-direction tucks |

| Artwork planning | Requires clear panel planning for “front” and tuck orientation | Often simpler for brands that want same-direction tuck alignment |

| Best fit | General retail, cosmetics, supplements, broad SKU ranges | Programs where opening direction and display behavior are tightly controlled |

If you want, you can request both dielines for comparison so your pack line and brand team can validate the best user experience before committing.

Functional Add-Ons

Reverse tuck cartons can be engineered beyond standard retail packs to support protection, compliance, and better consumer experience.

- Window options (project-based) for product visibility and premium display

- Tear strip / easy-open features for smoother consumer access

- Tamper evidence concepts for high-trust categories such as supplements and personal care

- Inner printing for brand storytelling or usage instructions

- Dividers/inserts (project-based) for multi-piece kits and bundle protection

Industry Fit and Common Use Cases

Cosmetics and Personal Care

You can combine premium board + controlled finishes to improve shelf appeal and perceived value. Reverse tuck cartons are commonly used for skincare, cosmetics, and fragrance-related secondary packaging.

Supplements and Wellness Products

RTE cartons support clear information layout, barcode readability, and consistent shelf-facing panels—useful for programs that must manage multiple variants and regulatory text blocks.

Food Dry Goods and Tea/Coffee Accessories

When your product is dry or wrapped goods, reverse tuck cartons deliver a clean retail pack with strong print potential and efficient packing.

Small Electronics and Accessories

For compact accessories, reverse tuck cartons provide a stable retail format while allowing optional inserts or compartments to reduce movement.

Artwork and Panel Planning

To avoid common production issues and speed up approvals, align early on:

- Front panel hierarchy (brand, product name, key claims)

- Side panels reserved for ingredients, warnings, usage, and multi-language text (if applicable)

- Barcode and batch/lot area placement for scanning reliability

- Finish placement (foil/UV/emboss) mapped to dieline folds to avoid distortion on creases

If you send your product dimensions and preferred shelf orientation, you can receive a dieline recommendation that reduces revision cycles.

Production Workflow and Quality Control

A stable folding carton program depends on repeatable approvals and measurable QC checkpoints.

Program Workflow You Can Expect

- Dieline confirmation and board recommendation

- Artwork review aligned to folds and finishing

- Sampling (plain and/or printed) for fit, assembly, and shelf tests

- Mass production with in-process checks

- Export packing aligned to transit and handling conditions

QC Focus Points for Reverse Tuck Cartons

- Print registration and color consistency across runs

- Die-cut accuracy and clean edges

- Crease quality to reduce cracking on folds

- Glue seam integrity and carton squareness

- Finish consistency (foil sharpness, UV placement, tactile uniformity)

Frequently Asked Questions

What information do you need to quote reverse tuck folding cartons?

Carton size, product weight, board preference, printing coverage, finishes, quantity, and destination country. If you do not have a dieline, you can request a recommended dieline and board selection based on your product.

Can you help me choose SBS vs WLC vs kraft?

Yes. The best choice depends on your visual goals, budget, product weight, and finish requirements. If you share your use case and target price position, you can receive a practical recommendation.

Do reverse tuck cartons work for automated packing?

Reverse tuck cartons are commonly used for efficient packing workflows. Final suitability depends on your machine setup, tolerances, and dieline design; you can validate through sampling before mass production.

Can you add windows, tear strips, or tamper features?

Yes, these features can be added as project-based options depending on structure and performance requirements.

How do you keep finishes consistent across repeat orders?

You lock approved artwork, board, and finishing references at sampling stage, then maintain the same specification stack for reorders.