Home - Straight Tuck Folding Cartons

Custom Straight Tuck Folding Cartons

Custom Straight Tuck End (STE) Folding Carton Packaging for Retail-Ready Brands

Straight tuck folding cartons—also called Straight Tuck End (STE) folding cartons—are one of the most widely specified carton styles for retail packaging because they combine clean shelf presentation, production efficiency, and reliable closure performance. If you are packaging cosmetics, personal care, pharmaceuticals, or lightweight consumer goods, straight tuck cartons help you keep front-panel graphics aligned, opening experience consistent, and packing line operations stable.

As an experienced folding carton manufacturer, we produce custom straight tuck folding cartons with flexible board options, high-precision die-cutting, and premium print finishing—so you can scale packaging output while protecting brand consistency across SKUs and markets.

| Item | Specification |

|---|---|

| Carton Type | Straight tuck folding cartons (Straight Tuck End / STE) |

| Material | Paperboard (options available by positioning & performance) |

| Printing | CMYK / Pantone |

| Finishing | Lamination, foil stamping, embossing, debossing, spot UV, soft-touch |

| Structure Options | Standard STE, windowed STE, dust flaps, reinforced panels |

| Suitable Product Weight | Best for lightweight to midweight retail goods (structure-dependent) |

| Size | Fully customized |

| MOQ | Determined by size, board choice, printing, and finishing |

What Are Straight Tuck Folding Cartons?

Straight tuck folding cartons are paperboard cartons where the top and bottom closure flaps tuck in from the same direction. In practical packaging terms, this “same-direction tuck” structure matters because it influences how your carton looks on shelf, how it opens in the consumer’s hand, and how efficiently it runs through automated production and packing processes.

A typical straight tuck end carton includes:

- A front and back panel for branding, compliance text, and retail display

- Side panels for supplementary messaging and barcodes

- Top and bottom tuck flaps that close from the same direction

- Optional dust flaps for improved closure alignment and protection

Straight tuck cartons are commonly used when you need:

- Consistent front-facing presentation for retail

- Reliable, repeatable opening and closing behavior

- A folding carton structure that is compatible with standard converting workflows

How the Straight Tuck End Structure Works

Straight tuck is not just a naming convention—it is a structural choice that affects appearance, operations, and product protection.

1) Same-Direction Tucking Supports Cleaner Shelf Presentation

Because both tucks are oriented the same way, you can design the carton so the main panels and graphics align more predictably in retail display. This helps when:

- Your packaging relies on a “hero panel” for brand recognition

- You want consistent front-panel alignment across different SKUs

- You need packaging that photographs well for e-commerce listings

2) Predictable Opening Experience Improves Consumer Handling

Straight tuck cartons are intuitive for consumers because the closure behaves consistently. A predictable opening sequence reduces:

- Frustration during unboxing

- Accidental tearing of the top panel

- Misalignment of flaps after re-closing

This matters for products that are opened frequently, such as personal care and cosmetics.

3) Converting & Packing Line Efficiency

From a manufacturing and filling perspective, straight tuck cartons are compatible with standard carton converting steps:

- Printing and finishing

- Die-cutting and creasing

- Folding and gluing

- Carton erection and product insertion

When correctly engineered, straight tuck cartons support stable forming and closure on semi-automatic or automatic packing lines—especially for lightweight products that require consistent carton geometry.

4) Closure Integrity for Lightweight Products

Straight tuck is typically selected when the product is relatively light and does not require a heavy-duty locking bottom. The structure provides reliable closure performance with:

- Proper tuck depth

- Accurate creasing

- Consistent board stiffness selection

For heavier items or products with high drop-risk, other bottom structures may be preferable—this is a key decision point addressed below.

Straight Tuck vs Reverse Tuck Folding Cartons

Buyers frequently compare Straight Tuck End (STE) with Reverse Tuck End (RTE) because they are visually similar but operationally different. Choosing the right one helps reduce production issues and improves shelf presentation.

Visual & Branding Considerations

- Straight Tuck (STE): Often preferred when you want the main panel orientation and shelf-facing consistency to be straightforward across top and bottom closures.

- Reverse Tuck (RTE): Tucks in opposite directions, which can influence how graphics align depending on the layout and production setup.

Packing Line & Handling

- STE: Frequently chosen when you want the opening direction to feel consistent and predictable, especially for products opened repeatedly.

- RTE: Can be practical depending on how cartons are erected and loaded, and sometimes suits certain pack line preferences.

Structural Fit by Product Type

- STE is commonly recommended for: cosmetics, skincare, personal care, pharmaceutical cartons, lightweight retail products.

- RTE can be chosen when: your artwork layout, packing direction, or operational process favors reverse tuck orientation.

When Straight Tuck May Not Be Ideal

Straight tuck is not a universal solution. You may want an alternative structure if:

- Your product is heavy and needs a stronger bottom structure

- You require tamper-resistant closure systems beyond standard tucks

- Your packaging requires extra stacking strength or drop performance

In these cases, bottom-lock structures or reinforced designs are often more appropriate.

Materials & Board Options for Straight Tuck Cartons

Board choice determines your carton’s stiffness, print quality, fold performance, and overall packaging feel. We help you select board specifications based on your product type, handling conditions, and brand positioning.

Common Board Categories

- Standard paperboard: Balanced cost and print performance for general retail packaging

- Higher stiffness boards: For improved structure retention and premium hand-feel

- Specialty surface papers: For textured or high-end brand experiences

How to Select the Right Board

A practical selection approach considers:

- Product weight and shape stability needs

- Shelf display requirements and carton size

- The desired tactile experience (premium vs standard)

- Finishing methods (foil, embossing, soft-touch)

- Packing line behavior (creasing performance and fold memory)

A carton that looks premium but folds poorly is a supply chain risk. Board selection should be a performance decision—not only a visual decision.

Customization Options

Straight tuck folding cartons are highly customizable, allowing you to tailor structure, visuals, and functionality to your market.

1) Size & Structural Customization

- Custom dimensions for single products or multi-unit sets

- Adjusted tuck depth and flap geometry for improved closure reliability

- Optional dust flaps for cleaner closure and internal protection

- Window cut-outs (with or without film) for product visibility

2) Printing & Brand Execution

- CMYK for photographic designs and gradients

- Pantone color matching for brand consistency

- High-resolution artwork reproduction for premium shelf impact

- Multi-language panel layouts for export markets

3) Finishing & Shelf Differentiation

- Matte or gloss lamination for surface protection and appearance

- Hot foil stamping for logo and accent highlights

- Embossing/debossing for tactile brand cues

- Spot UV for contrast and premium visual layering

- Soft-touch coating for luxury unboxing perception

4) Functional Add-Ons

- Tamper-evident sealing areas (label or seal integration)

- Easy-open features for improved user experience

- Reinforced corners for better shape retention

- Barcode placement planning for retail scanning reliability

Typical Industries & Use Cases

Straight tuck folding cartons are most effective when you need a retail-ready carton with consistent presentation and strong branding potential.

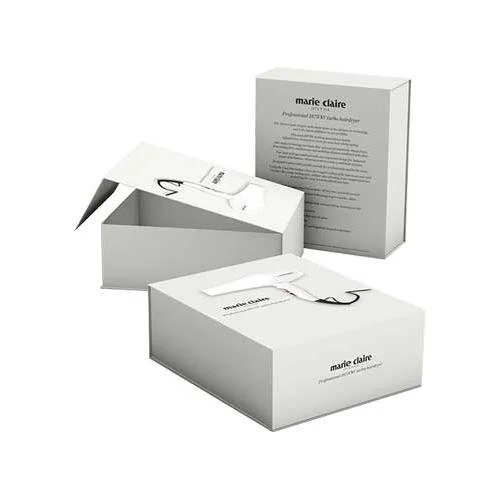

Cosmetics & Skincare Packaging

Ideal for serums, creams, lotions, and premium skincare products where shelf appearance and finish quality directly influence conversion.

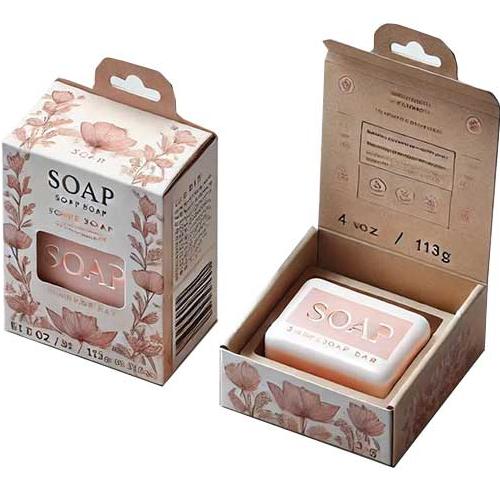

Personal Care & Toiletries

Works well for items like soaps, grooming products, and daily care SKUs that require reliable folding cartons at scale.

Pharmaceutical & Health Packaging

Straight tuck cartons are commonly used for OTC products and compliant retail packaging formats where information layout and consistency matter.

Lightweight Food & Confectionery Packaging

Suitable for selected dry goods and confectionery formats where carton presentation and brand differentiation are key.

General Retail Consumer Goods

For lightweight accessories and consumer items that require efficient packaging and strong printing performance.

Manufacturing Process & Quality Control

A straight tuck carton must be engineered for both appearance and performance. Our process focuses on print accuracy, die-line precision, and consistent folding behavior.

Production Workflow

- Material selection aligned with performance needs

- Printing and finishing to match brand requirements

- Die-cutting and creasing for accurate folding geometry

- Folding and gluing to ensure stable carton shape

- Final inspection to confirm closure behavior and visual consistency

Quality Control Focus Areas

- Color consistency across batches for brand continuity

- Die-cut accuracy for clean edges and reliable assembly

- Crease performance to avoid cracking and distortion

- Glue strength and panel alignment

- Sampling inspections for stability during storage and transport

This level of control helps you avoid common operational issues such as flap misalignment, inconsistent carton geometry, or print variations across large orders.

Why Choose Us for Straight Tuck Folding Cartons

You need a manufacturer that can deliver more than “printing.” Straight tuck cartons require precision converting, structural understanding, and stable mass production capability.

- Reliable manufacturing for bulk and repeat orders

- Structural customization to fit your product and packing process

- Strong print and finishing capability for retail impact

- Export-ready communication and documentation support

- OEM and private label support for multi-market branding

Our goal is to help you reduce packaging risk, protect brand consistency, and scale carton production efficiently.

Frequently Asked Questions (FAQ)

What is a straight tuck end (STE) folding carton?

A straight tuck end folding carton is a paperboard carton where the top and bottom tuck flaps close from the same direction, supporting consistent presentation and predictable opening behavior.

How is straight tuck different from reverse tuck?

Straight tuck closes in the same direction at top and bottom, while reverse tuck closes in opposite directions. The choice depends on branding layout, shelf presentation needs, and packing line preferences.

When should you choose straight tuck folding cartons?

Straight tuck cartons are commonly chosen for cosmetics, personal care, pharmaceuticals, and lightweight retail goods where printing quality and shelf presentation are priorities.

Can straight tuck cartons include windows and premium finishes?

Yes. Straight tuck cartons can be customized with window cut-outs, lamination, foil stamping, embossing, spot UV, and other premium finishing options.

What is the minimum order quantity?

MOQ depends on carton size, board choice, printing method, and finishing requirements. Share your specifications to receive an accurate quotation.

Request a Custom Straight Tuck Folding Carton Quote

If you are sourcing straight tuck folding cartons for branded retail packaging, contact us with your product size, target market, and finishing requirements. We will recommend structure, materials, and print options that match your performance and branding goals, and provide a production-ready quotation.